Track Record of Installation and Monitoring on a Wide Variety of Rotating Equipment (Pumps, Fans, Conveyors, etc.

Here are actual photos of conanair in use. conanair can be used for the predictive maintenance of Motors, Pumps, Fans, Blowers, Compressors, Turbines, Freezers, Air Conditioners, Dust Collectors, Conveyors, Screw Extruders, Molding Machines, Roll Machines, Reducers, Gearboxes, Mixers, Machine Tools, and more.

Usage Scenes by Industry and Equipment

Vibration Monitoring in Factories and Manufacturing Equipment (Compressors, Conveyors, Machine Tools)

These are monitoring examples for rotating equipment such as motors, compressors, and conveyors, where line stoppages lead to significant losses. conanair safely and wirelessly collects vibration data from locations that are difficult for humans to inspect, such as high places, narrow spaces, and inside covers.

Iron Ore Conveyor Pulley |

Chip Conveyor Motor |

|---|---|

|

|

Bag Filter Screw Conveyor |

|

|---|---|

|

|

Fin Fan Cooler |

Steam Turbine |

|---|---|

|

|

Gearbox |

Blower Motor |

|---|---|

|

|

Iron Ore Conveyor Pulley

Chip Conveyor Motor

Bag Filter Screw Conveyor

Fin Fan Cooler

Steam Turbine

Gearbox

Blower Motor

Predictive Maintenance for Buildings and Public Infrastructure (HVAC Fans, Water Pumps, Boilers)

These are monitoring examples for air conditioners and water supply pumps essential for hospitals, commercial facilities, and water treatment plants. For critical equipment requiring 24-hour operation, conanair detects early bearing anomalies often missed by visual or auditory inspection, supporting safe facility operation.

Water Pump & Motor 37kw |

Boiler Feed Water Pump |

|---|---|

|

|

Sewage Sludge Pump |

|

|---|---|

|

|

Sewage Sludge Pump |

Air Blower |

|---|---|

|

|

Water Pump & Motor 37kw

Boiler Feed Water Pump

Sewage Sludge Pump

Air Blower

Primary Industries and Others (Aquaculture Equipment, Agitators, Sludge Sweepers)

These are examples of machinery used in harsh environments such as agriculture, fisheries, and sewage treatment. For equipment like aquaculture machines and sludge sweepers where failure causes secondary damage, conanair provides a low-cost, reliable "health check" for machines.

Agitator Motor |

|

|---|---|

|

|

Sludge Sweeper |

|

|---|---|

|

|

Agitator Motor

Sludge Sweeper

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

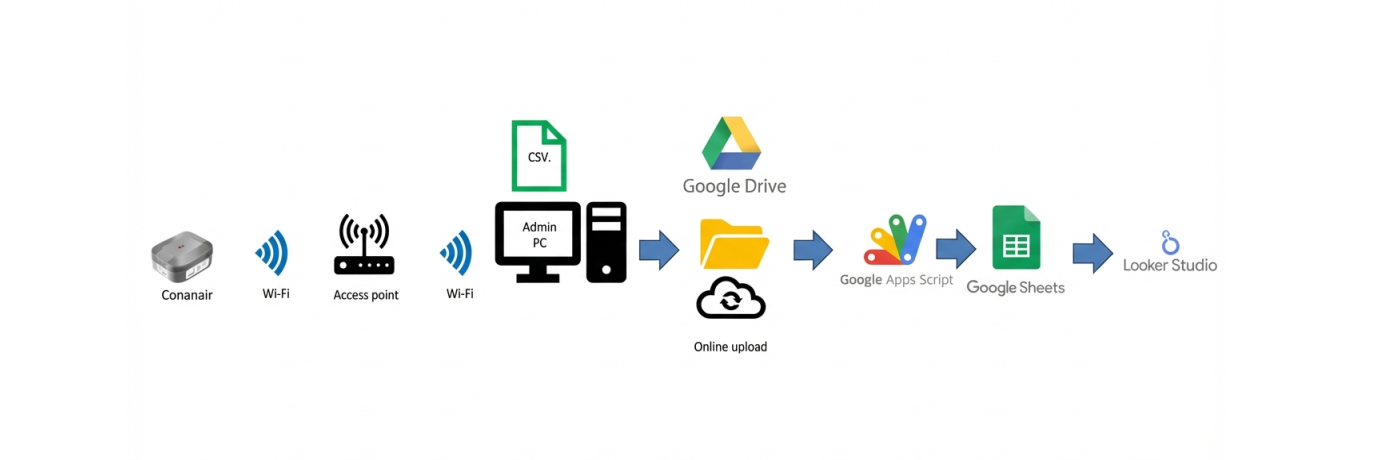

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |