Evolution from Analog to Digital: Benefits of IoT Vibration Measurement

What is IoT? Why are IoT and Vibration Sensors related to each other? Learn how to use Sensors with IoT efficiently.

What is IoT?

For those who are not tech-savvy, IoT might sound like an acronym unique to technology specialists. IoT stands for Internet of Things. It is a network of devices linked with sensors, software, and other technologies that send data and information across the internet without human interaction. Thus, this is relevant for many people, even if they do not work in technology. This is important for any business too.

What kind of data is sent with IoT?

IoT sends large amounts of data about the machine’s surrounding environment, such as weather conditions, traffic patterns, human behavior, and other factors. All of this data is important for accurate technology’s capabilities. There is an astonishing amount of IoT Sensors such as Temperature Sensors, Weather, etc.

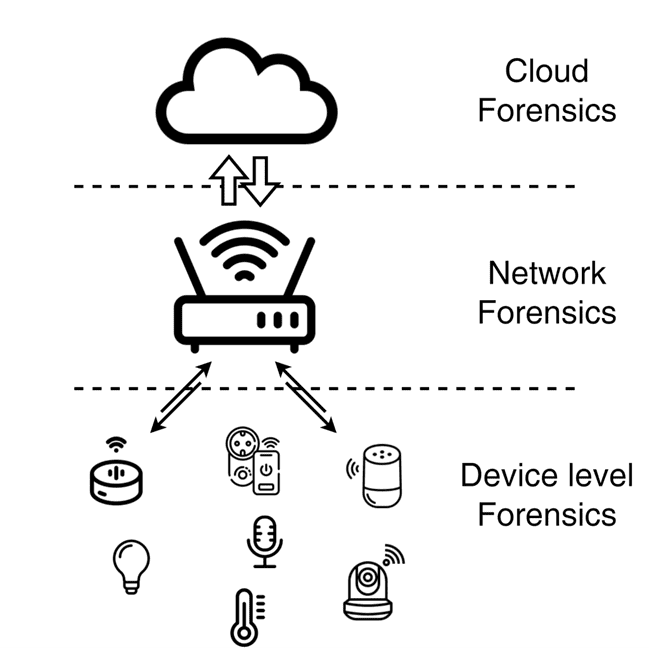

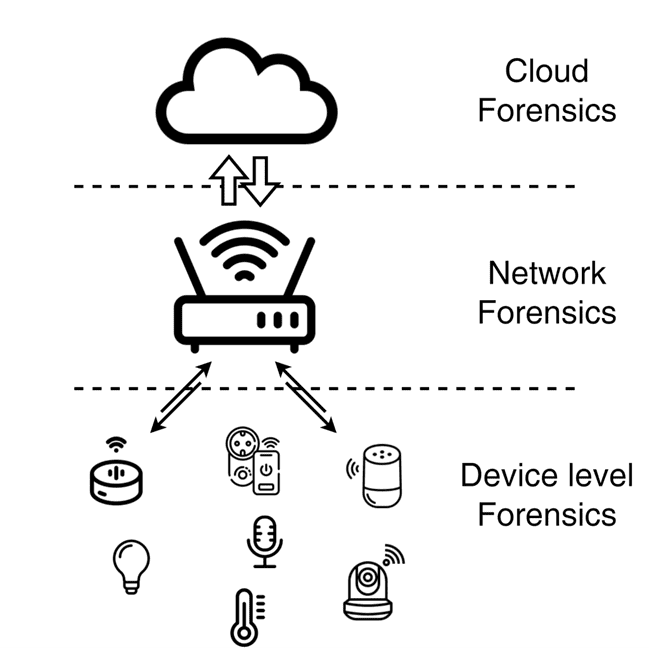

The collected data is used to improve future iterations or versions of the product or parts. The critical goal of any IoT system is to detect issues before they become serious, saving time and money in the long run. Most of this data is usually collected and housed within a cloud.

What is an IoT Vibration Sensor?

We live in a generation where people depend on support from devices. Thus, the devices need to know where they are at. This means the device should collect and send data on the temperature, humidity, etc., of the surrounding environment.

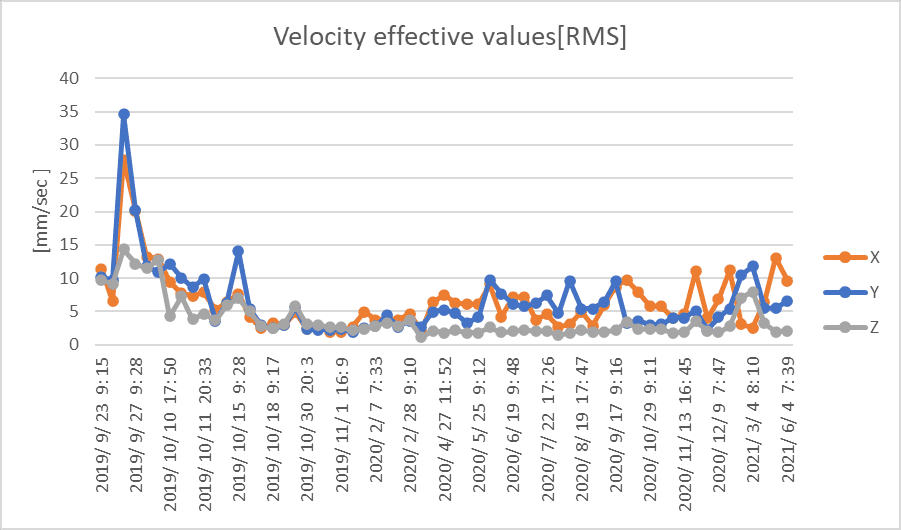

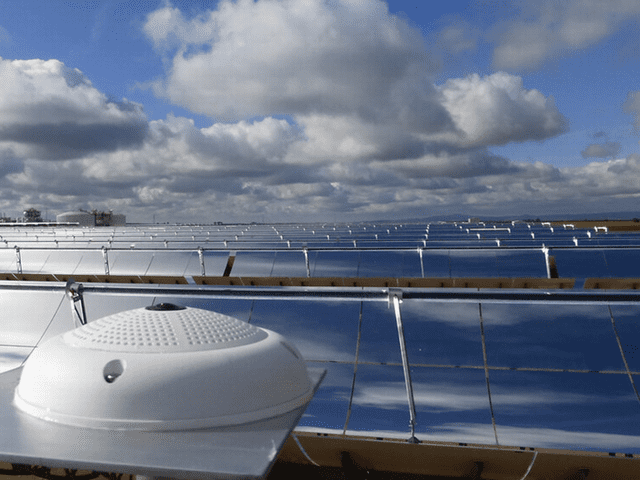

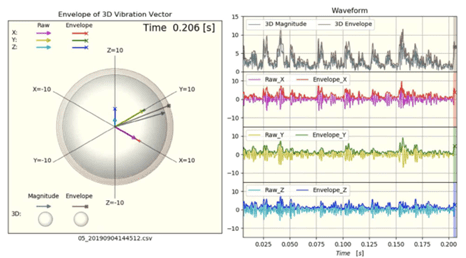

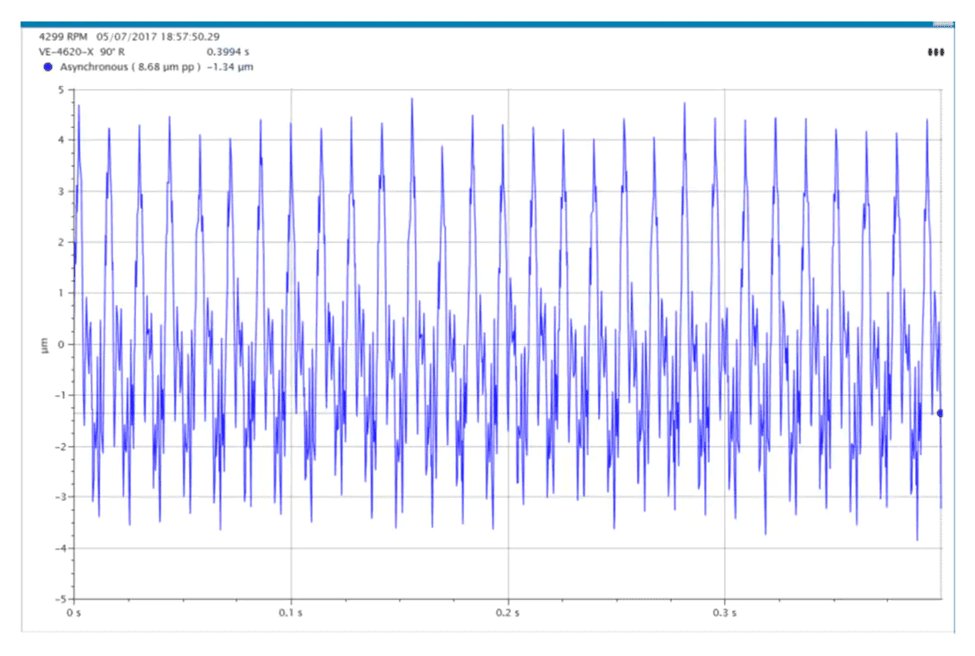

An IoT Vibration Sensor is a device that reads vibration data and sends it to a Cloud, User Interface, or Local Servers for analysis purposes. The vibration data can be used for daily monitoring and early alert for possible issues. These issues will probably lead businesses to high-priced consequences when ignored or undetected. Generally, most IoT Vibration Sensors are battery-powered, but some are powered externally. Most of these devices are placed directly on top of a machine with industrial-strength magnets. Furthermore, IoT Vibration Sensors use MEMS-based technology, which allows measurements to be taken from three axes and various bandwidths.

Here are some applications of different types of vibration sensors.

- Used as an automatic shutdown switch due to excessive vibration of machinery

- Used to shut down home appliances such as washing machines

- Used in toys and games

- Used as a shock sensor while the device is being transported

Despite the name, vibration sensors detect more than just acceleration. They also detect acceleration, velocity, displacement, and frequencies. For example, on industrial machinery, all of these factors will help businesses detect looseness, increase in the machine’s temperature, or bad bearing.

The IoT Vibration Sensors typically consist of wireless battery-powered industrial sensor nodes.

What causes vibrations to happen?

As mentioned, IoT Vibration sensors detect vibration from the object in question. Thus, what are the few key issues that can cause vibration?

- Wear : Wear comes from simple overuse or poor installation. For example, a belt that lacks lubrication can cause wear.

- Unbalance : Worn out ball, bearing, gear, or belt may cause vibration, resulting from simple overuse or poor installation.

- Looseness

- Misalignment : Misalignment occurs when two rotating shafts are not parallel to one another. Misalignment causes are improper installation of components or increasing temperature between the shafts.

- Temperature

What is the difference between Contact and Non-Contact Vibration Sensors?

If vibration sensors were broken down into two categories, contact and non-contact.

Contact

Contact sensors require placing the transducer on the object itself. The advantage is that it allows businesses to measure absolute motion. However, this requires slightly modifying the vibration environment, such as adding a mission to change the mode shapes and frequencies. A suitable coupling between the sensor and the test article provides accurate measurements.

Example of Contact Vibration Sensors

Accelerometer, Strain Gauge, Velocity Sensor, Gyroscope

Non-Contact

There are two primary reasons why non-contact sensors exist.

- The mass of the accelerometer would affect the vibration.

- Rotating equipment makes wiring virtually impossible.

Hence, why the existence of non-contact sensors came into existence; while this idea is hard to imagine, non-contact measurements can be done using lasers and sounds.

Example of Non-Contact Vibration Sensors

Microphone or Acoustic Pressure Sensor, Laser Displacement Sensor, Eddy Current or Capacitive Displacement Sensors.

What are the different types of vibration sensors?

Vibration measurement tools come in both wired and wireless sensors. Both have their tangible benefits and drawbacks. Depending on what the priorities are, businesses will have to choose.

Wired Vibration Sensors

Wired vibration sensors are connected to the network with ethernet cables.

- Advantage : This allows for a high-speed and reliable connection so that sensors can transmit data continuously.

- Disadvantage : The installation and setup process takes time and is costly. This is a drawback for businesses that are operating on a tight budget. Furthermore, companies will need more work to scale wired vibration monitoring systems.

Wireless Vibration Sensors

Wireless sensors, as the name implies, are usually connected through a wireless network. Data is transmitted as a batch instead of a continuous stream. Typically, wireless sensors are battery-powered.

- Advantage : Typically, wireless vibration sensors offer convenient options and low-cost installation. Wireless means businesses do not need to run cables through walls and ceilings. Furthermore, wireless excels at covering a large and remote monitoring area. Additionally, wireless monitoring systems are easier to scale, and businesses do not need to worry about additional labor time since it is wireless. With an internet connection it is also easy to access from anywhere with an internet connection.

- Disadvantage : Like any wireless connection, there will be concerns about connectivity issues. For example, warehouse-based businesses will face interference from pallet racking or other storage materials. Furthermore, additional maintenance might be required, such as battery issues.

Different types of vibration based on the working principles and constructions

Pin And Spring Vibration Sensor

The simplest type of vibration sensor as it consists of a small and thin pin in the center of a coil spring. The spring is anchored at its base, and the other end vibrates freely.

- Advantage : The low cost, ability to respond to two out of the three axes, no power supply requirement

- Disadvantage : It requires a latching component such as a flip flop as internal contact is brief.

Piezoelectric Chip

It is made of piezoelectric polymer film laminated to a polyester substrate. It comes in both unweighted and weighted versions, where the additional weight changes the resonant frequency of the vibration sensor.

- Advantage : It has a resonant frequency of about 170 Hz when no weight is attached to its end.

- Disadvantage : It generates voltage during the process of deflection.

Mousetrap

A sensor type that relies on a simple system of leverage similar to a mouse tap. Commonly used in power station cooling towers.

Magnetic

The magnetic vibration sensor is used to detect excessive vibration in machines or other devices which contain mechanical rotation parts. These sensors are usually larger in size and handle a larger current of frequencies.

What are the different examples?

As a business, there are various instrumentation and software options to choose from for measuring vibration. Here are the following different sensor types.

Accelerometer

Probably the most popular vibration sensor type. As the name implies, accelerometers measure acceleration levels. For example, Aerospace companies use data from IoT sensors to track the performance of an aircraft.

- Good to use for general-purpose shock and vibration.

- Not suitable to use for a limited budget and access to necessary electronics.

- Examples include Piezoelectric Accelerometer, Piezoresistive Accelerometer, and Capacitive MEMS.

- Pros : They are trendy, have different options, and are accurate with low noise.

- Cons : Businesses must integrate for velocity and displacement and might require additional supporting electronics.

Strain Gauge

A foil with an electrically conductive grid that can be stretched or compressed where the electrical resistance of the grid increases or decreases proportionally.

- Good for curved surfaces or when size and mass are important

- Not good when there are time constraints or a need to measure acceleration.

- Pros : They come in different options and are inexpensive and are very accurate, and cover a wide frequency range.

- Cons : Installation is not easy and requires special electronics.

Velocity Sensor

- Good for applications with high temperatures.

- Compared to others, they are hard to find.

- Pros : They measure velocity directly and covers.

Gyroscope

A sensor that uses MEMS technology and has three small resonating masses that get shifted as the angular velocity changes. They are helpful compared to accelerometers because they provide a frame of reference that an accelerometer does not have.

- Recommended if orientation data is required.

- Pros : Gyroscopes measure rotation, and typically MEMS are low-cost.

- Cons : Gyroscopes should be used with an accelerometer to measure orientation.

Microphone or Acoustic Pressure Sensor

Using sound for vibration measurement might be foreign to most people. However, recall that sound is a vibration that travels through the air in the form of pressure waves.

- Good to use for health monitoring and determining vibration frequency.

- Not suitable for measuring acceleration directly and determining vibration at known locations.

- Example: PCB Piezotronics

Laser Displacement

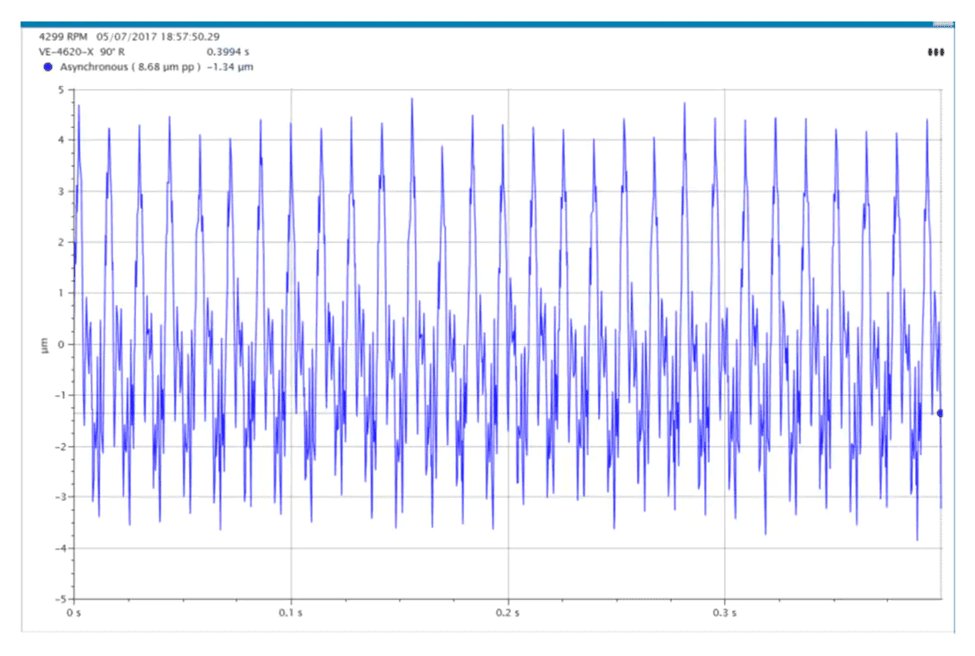

As the name implies, Laser Displacement uses lasers with a triangulation of transmitting and receiving lenses. As the target moves closer and farther away, the angle of the reflected light changes as the laser is focused on a different position on the receiving element. This is commonly used for objects that prevent using accelerometers, such as rotating components.

- Good to use for measuring displacement directly without altering the structure or product.

- Not suitable to use if power is a concern.

- Example: KEYENCE

Eddy Current or Capacitive Displacement

Eddy Current and capacitive displacement sensors measure the distance between themselves and a target. They provide a way to “measure vibration through the air” without altering the vibration system.

- Good to use to measure displacement directly without altering the structure or product.

- Not a good use if power is a concern.

- Difference between Eddy Current or Capacitive Displacement.

- Capacitive sensor uses a high-intensity electric field it generates.

- Eddy-current sensor creates a magnetic field and measures the changing response of that field.

- Example Lion Precision

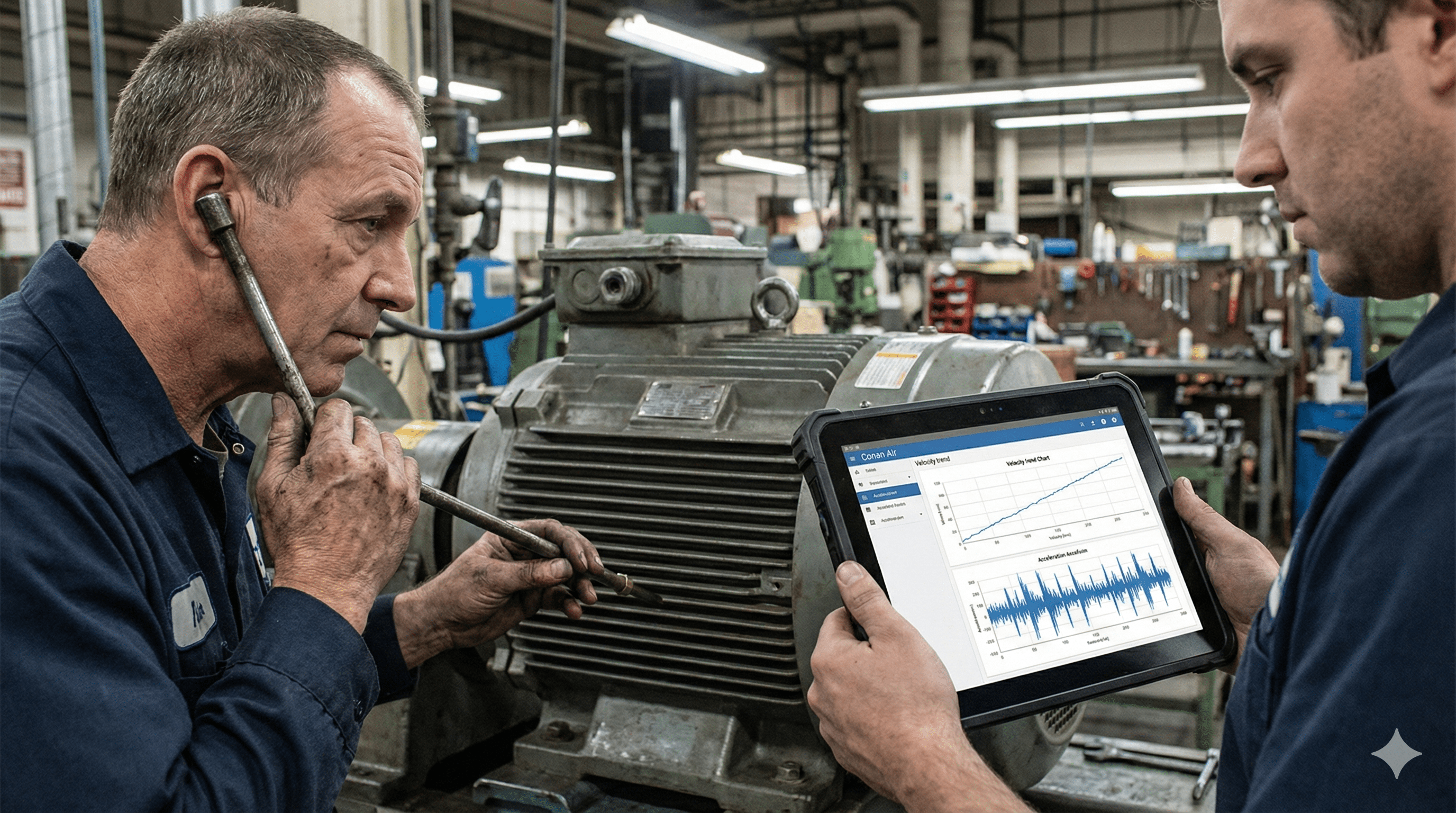

Vibration Meter

Vibration meters offer a real-time vibration analysis in a handheld unit. This allows for maintenance decisions to be made quickly. They provide RMS and peak-to-peak levels in real-time and sometimes include the resonant frequency of the vibration.

- Good to use because they provide a quick diagnosis of machinery.

- Not suitable for transient events and longer than 15 seconds of tests.

- Example Fluke

Vibration Data Logger

Vibration Data Logger provides a cost-effective way to capture vibration data quickly and easily. They combine all the components necessary for most entry to mid-level vibration testing applications.

- Good to use for businesses that are interested in saving time and costs

- Not suitable to use for modal testing; high-speed sampling needed.

- Example enDAQ (a division of Mide Technology)

Why should you care about IoT Vibration Sensors?

In the past, businesses such as factories would call in a specialist for an annual machine check-up. Generally, these specialists would manually inspect, but they can check the distance or remain the distance between these sensors.

How to choose IoT Vibration Sensors?

When looking at the data collected from vibration sensors, there are different factors to consider when concluding.

Sensor Data Integrity

Sensors must operate with a reasonable transmission rate. The rate at which data is sent or received must be reliable and consistent. Furthermore, the data must be accurate.

Security

Vibration sensors must transmit data to the cloud system in a secure manner or ensure optimal security.

Data Harvesting

What key data or information are you interested in collecting as a business? Typical sensors collect and share data related to temperature, acceleration, velocity, frequencies, and displacement. Furthermore, what is the time range of data collection you are interested in as a business? Most vibration sensors are handheld devices. Data collected in a handheld device is usually real-time based, implying that the data will not be continuous.

Adaptability

It is essential to know the primary mechanism of the machine from which the reading is taken.

Cloud or Local Computing

Where is your business storing the collected data? Devices can pass the collected data onto any cloud service or local non-platforms such as PCs or servers.

Ease of Installation

Installing the sensors will be essential, no matter how big your facility is. However, the difference will be “how” the installation would occur. Some contact-type sensors can be placed on top.

Wireless Range

Businesses should be aware of the frequency of the sensors. Lower frequencies will require a different gateway, leading to possible range issues. Furthermore, working indoors and outdoors will change the frequency levels necessary.

Battery Life

Various vibration sensors have different battery life. For example, businesses that transmit data every 2 hours can expect a battery life of about eight years. Additionally, frequent usage will shorten the battery life.

Hidden Cost

Besides the vibration sensors, there might be additional costs, such as Cloud Services, that you might be unaware of.

What are the benefits of using IoT Vibration Sensors?

With all these different types and examples, some might be intimidated by vibration sensors to the point where they will scrap the idea of using them. If that is the case, you miss out on the benefits or positives.

Understand the causes of damage

There are various reasons for machines to wear out. Whatever the reason, business needs to understand why it happened. By monitoring vibration, companies can track down the root source of the vibration and damage.

Monitor repair needs

Businesses that monitor vibration in real-time will have up-to-date information on when to perform repair work.

Keep an overall health check on equipment

Real-time monitoring will allow businesses to know when to call for repairs or know which parts specifically to replace. This will enable businesses to save money.

Improved Safety

Not only is the worn-out system fatal to a business but also to the workers. Safety is the number one priority for any facility. Furthermore, it was shown that wireless vibration sensors have a high chance of reducing risks as they cut down on visits.

Cost in the long run

Some businesses might fear implementing these new systems because of the cost. While installing new vibration sensors might be expensive in the short run, it will be beneficial in the long run. The cost of damaged parts and loss caused by those damaged parts will be higher.

Who will benefit?

Anyone who operates rotating or reciprocating machinery can benefit. An example is fans, as the blades will collect deposits that can lead to less efficiency.

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

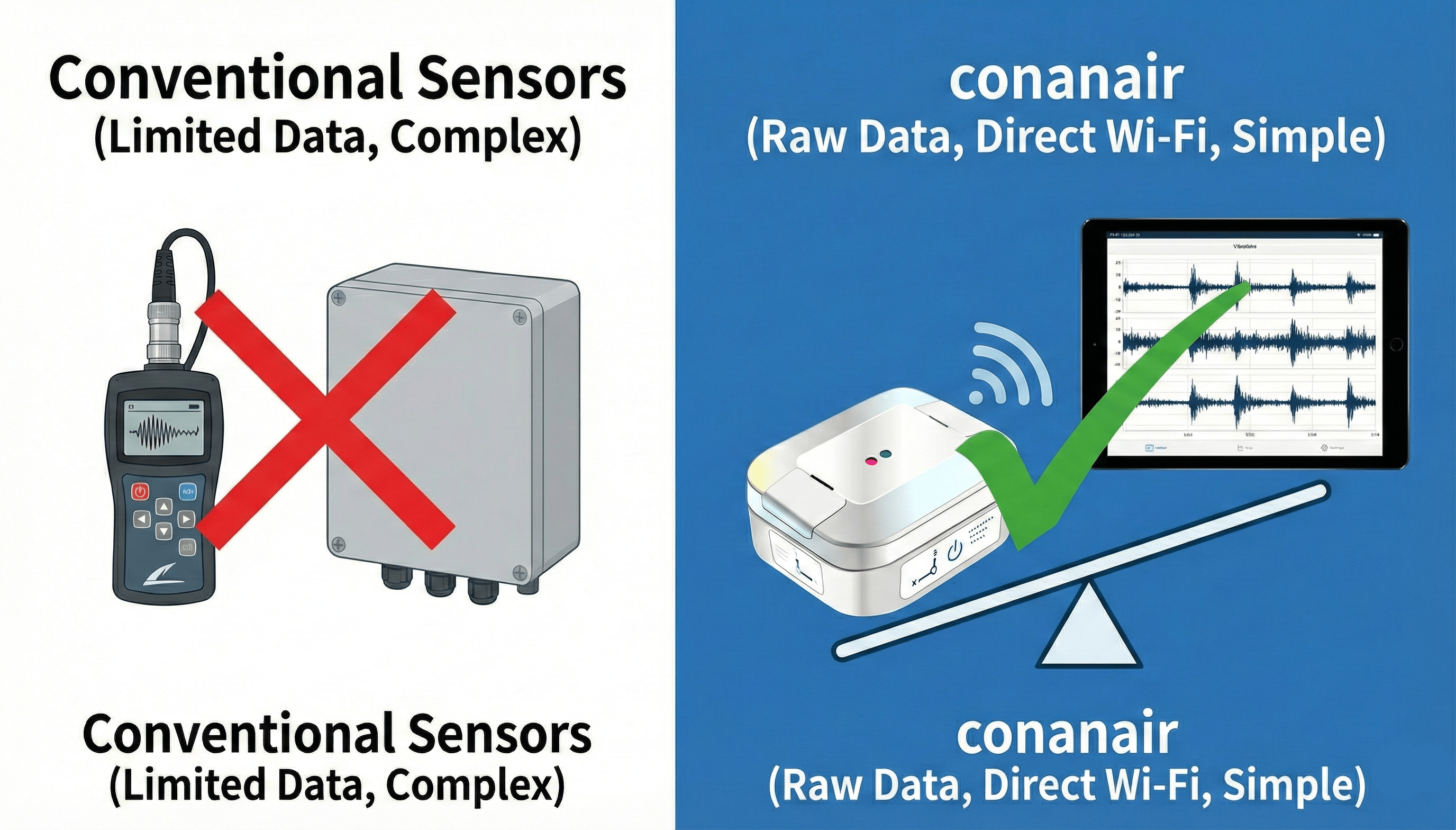

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |