Types of Vibration Sensors and Why "conanair" is the Best Choice for Maintenance

What is a vibration sensor for? Despite the significant benefits of vibration sensing, some businesses might be intimidated by the technology. “conanair” is often the best choice for any business.

What is a Vibration Sensor?

Introduction

As a business, it is important to keep a check on the health of your employees and the functionality of all devices. One way to keep check is using Vibration Sensors. These tools made their debut in the early 1900s as large mechanical devices used to measure and record tractive and brake effort in the automotive industry. The device consisted of two tracing pens centered and mounted above a paper scroll. This device was essential in measuring acceleration. Today, most vibration sensors are electronic devices that measure the amount and frequency of vibration in a given system or equipment. Furthermore, there are various industrial areas that employ vibration sensors. The following are brief examples of those different areas: aerospace, automotive, metalworking, oil and gas refining, and etc.

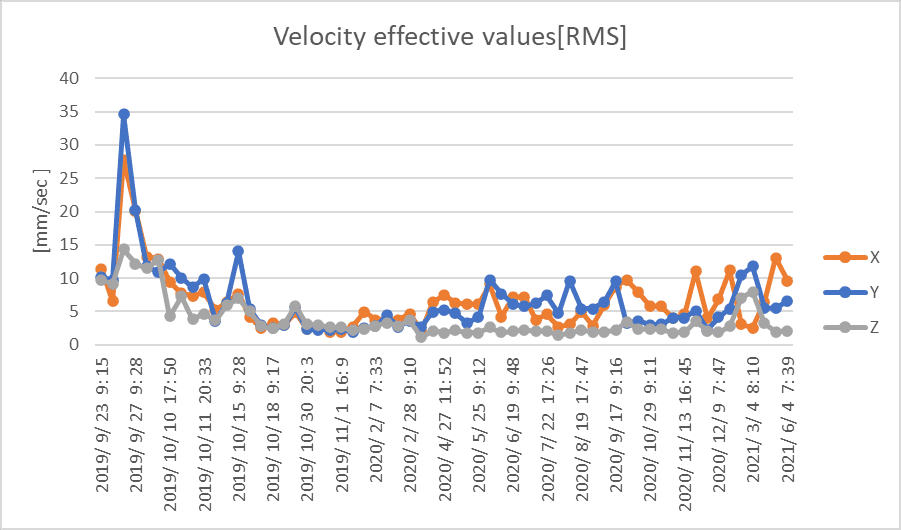

Vibration sensors are monitored by directly or wirelessly connecting to a device. The two key data types collected frequency, the measure of how often vibration occurs, and intensity, the measure of how high the vibration is. The measured data is collected and logged down for comparison purposes. You will be able to predict failures by comparing the different trends of frequency and intensity.

The Seven Types Of Vibration Sensors

We have introduced vibration measurement sensors on this page [The Basics Behind IOT Vibration Sensors], but the uses of each of the seven typical vibration sensors are as follows:

- Accelerometers : The most common type of vibration sensor measures the change of velocity (a.k.a acceleration) of a given component. The change of velocity is represented by an electrical signal which is interpreted to produce vibration data. Common examples of accelerometers include piezoelectric accelerometers and piezoresistive accelerometers.

- Strain Gauges : This is a foil that is directly applied to the surface of the machine being monitored. The purpose is to get readings that measure the vibration of an object.

- Eddy-Currents : This is a non-contact sensor that produces magnetic fields which are used to measure the relative movement of a given object. The sensor measures relative movement. The sensors are frequently used in laboratories where fragile equipment is used and measurements need to be precise.

- Laser Displacement : Another type of non-contact sensor where it uses a laser beam with triangulation where it detects the change of the beam’s position towards an object. They work better with stationary objects in clean settings and will not interfere with delicate instrumentation.

- Gyroscopes : This is a contact sensor that measures angular velocity (how quickly something turns or rotates). Gyroscopes can be used together with accelerometers on rotating equipment filling in gaps in the data provided.

- Microphone Sensors : Sensors that detect change that might occur in high frequency vibration that is undetectable with the human ear. They can accurately detect changes in vibration frequency but not absolute values.

- Vibration Meters : Vibration meters are handheld devices that analyze vibration data and place it as a readable format. They are usually used to perform quick checkups on assets.

Why use wireless vibration sensors?

In the past, accelerations were measured with vibration sensors. Today, vibration sensors are used to measure the frequency of vibration to detect imbalances or issues in the asset and predict future breakdowns. This is important for any business that uses heavy equipment in its daily operations. The following are the advantages of monitoring vibrations.

- Businesses will have a better understanding of the causes of damage : Vibration analysis can help with Root Cause Analysis (RCA), the systematic process of identifying the origin of certain issues or incidents. Businesses that monitor frequently can track down the source of issues leading to great damages and additional costs.

- Helps businesses monitor their repair needs : Does your business practice Predictive Maintenance (PdM), real-time condition-based maintenance that checks the conditions of their devices? The major benefit of this practice is the real-time data. With real-time data, you will be kept up to date to see which parts need repair or not. For example, detecting underlying problems of a chemical plant at an early stage allows rectification of issues before affecting other processes.

- Businesses can maintain an overall health check on their equipment : As a business, it is essential to keep an eye on everything. For instance, when your employee is sick, they will also perform in that manner. Similarly, it is important to maintain a healthy machine. This is done by relying on vibration sensors. Businesses can see which parts are performing well or which parts need repairing or replacement. For example, a food processing factory needs to maintain the performance of the rotating machinery parts in a conveyor system. Otherwise, it will lead to losses of many high costs.

Who should use vibration sensing?

Previously, it was mentioned that vibration sensing is used in a wide range of industries. If you are a business that uses a wide range of machines such as the following, vibration sensing will be your companion.

- Water Pumps : Vibration sensors help make sure water pumps and condensers operate smoothly, providing advanced warning on potential issues.

- Motors : Motors rely on rotating components and vibration sensing can prevent minor imbalances in individual machines from becoming major issues.

- Fans : Fans also rely on rotating equipment that must run smoothly. Businesses can use vibration data to detect issues early to minimize repair costs.

Thus, if your business requires machine maintenance, then you should be practicing vibration sensing.

What is “conanair”?

Despite the major benefits associated with vibration sensing, some businesses might be intimidated by it. As a business, you should not be afraid. Rather, think about the smart financial decisions you can make. This can be done with “conanair”.

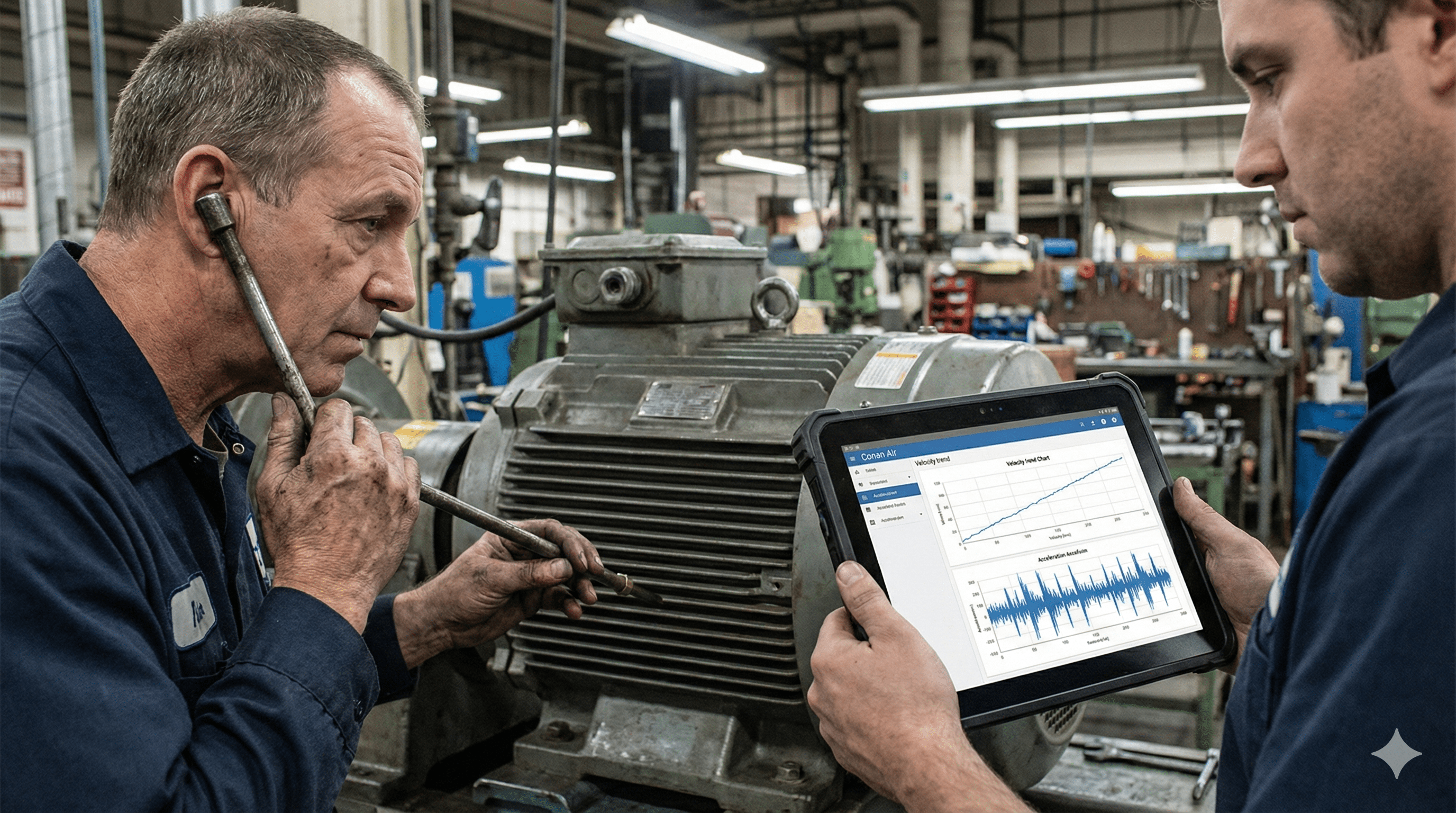

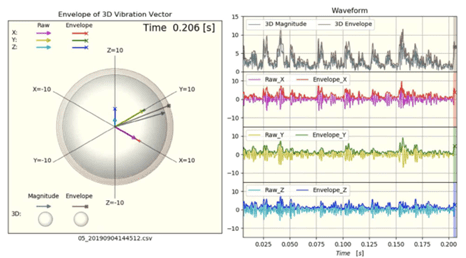

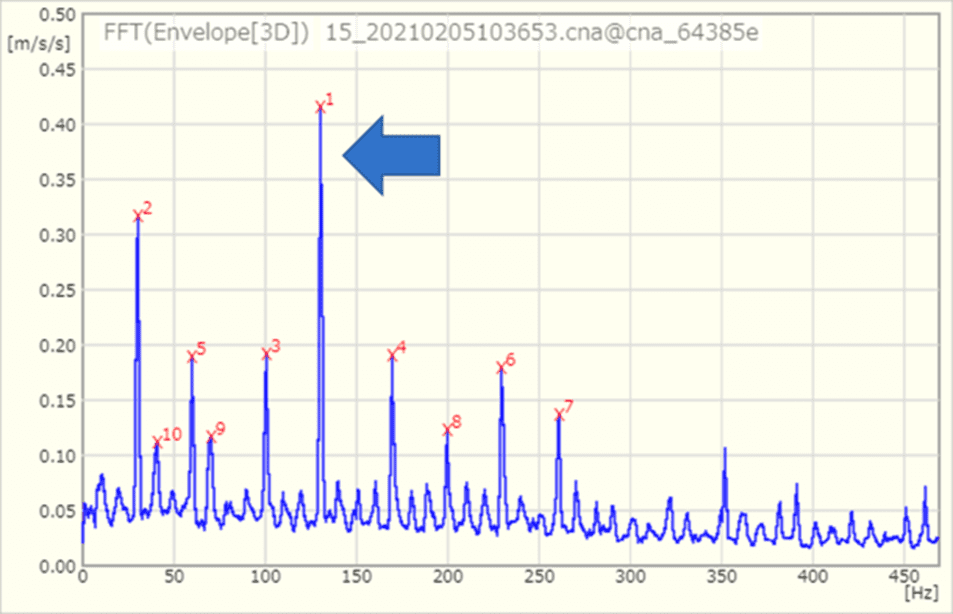

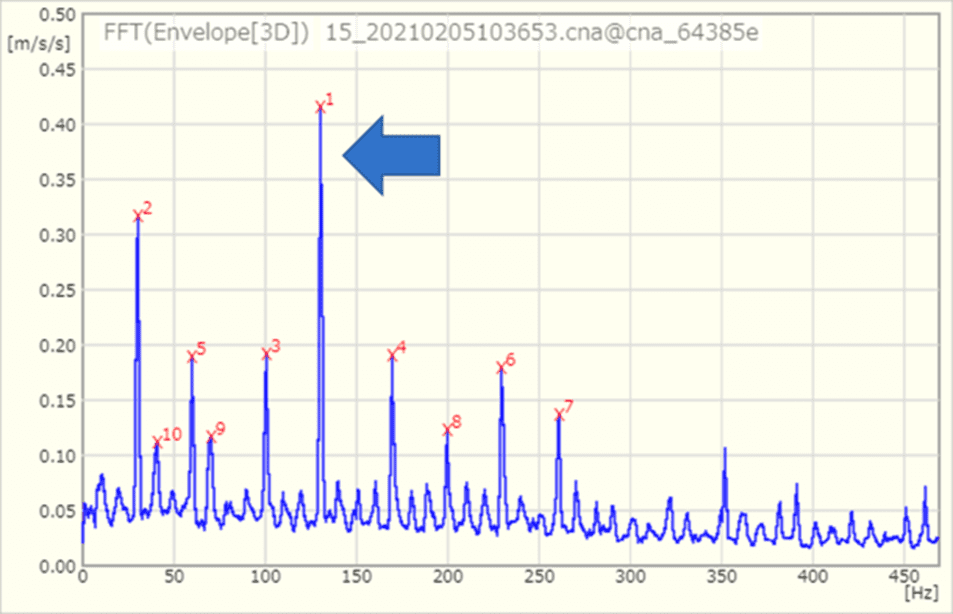

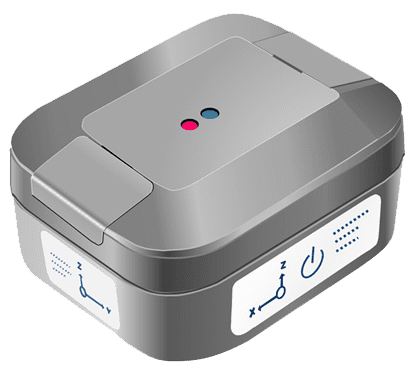

Convenient size and usage

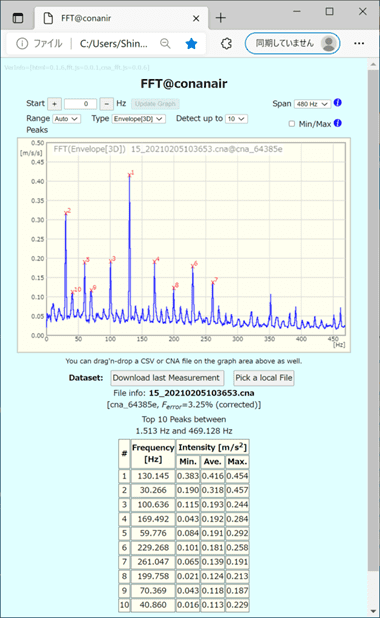

“conanair” is a wireless, battery-powered, compact-sized vibration sensor created by NSXe Co. LTD. The company is based in Mie Prefecture, Japan, and specializes in construction within factory-based facilities. Generally, vibrations are diagnosed from frequency analysis from using Fast Fourier Transform (FFT) and a high-frequency band. “conanair” has 1 kHz, a low-frequency band compared to others, but from simultaneously measuring and storing vibration data in three axial directions, it can perform the same vibration sensing compared to an average device. Furthermore, “conanair” can detect with higher sensitivity and less noise as possible because it synthesizes the envelope waveforms of each of the 3-axis vibration waveforms.

Easy access from browser

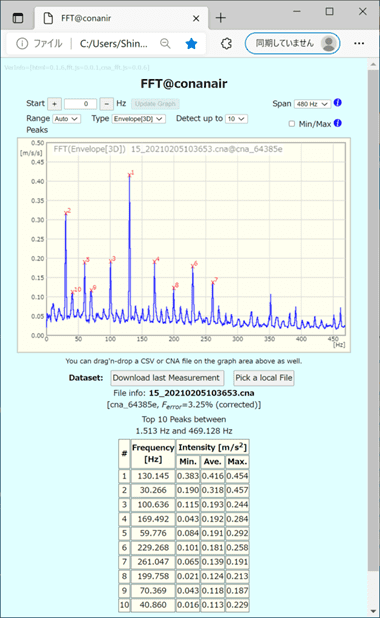

“conanair” is a perfect device for businesses that are easily intimidated by technology. No additional system applications or updates are required to perform vibration analysis with “conanair”. The device can be attached to the machine through simple magnetic placement. Measurements can be taken down and analyzed immediately through your smartphone or computer’s browser. Moreover, you can schedule when to measure within the range of every 30 minutes to every month or perform them on demand. Also, you can drag down past data and use it for comparison purposes or export the data in a . CSV format. Below is a sample screenshot of a browser with frequency analysis.

Easy steps of implementation

To summarize, here is a brief explanation of the steps on using “conanair”.

- Place “conanair” on your device with magnetic connection.

- From the device of your choice, select “conanair” from the Wi-Fi settings

- Open your browser and head to 192.168.5.1

- Touch the measurement button and get the results

- Check the values to perform health maintenance of the machine

Below are the general specs of “conanair”.

Hardware Specs

- Model : CNA-WLVS-02L

- Acceleration Range (m/sec2) : ± 160

- Axis of Measurement : 3-axis (X,Y,Z) and 3D Composite Value

- Acceleration Response (Hz) : 10~1,000, In case of HPF bypass ; 0~1,000 (-3db in both cases)

- Sampling Rate (Hz) : 3200

- A/D Resolution : 13bit

- Networking : Wi-Fi IEEE 802.11b/g/n (2.4GHz)

- Power Supply : Non-Rechargeable Li-Ion Battery CR2 x 1pc

- Operation Time : Continuous 8 hours (Not Continuous Measuring)

- Intermittent : 4 years (Daily Once Measurement)

- Electric Consumption (mA) : 100

- Size (mm) : 65×52×27(32) (with magnet)

- Weight (g) : 54 (77) (with magnet and battery)

- Ingress Protection Rating : IP67

- Temperature Range (℃) : -10 to 60°C

- Browsers : Google Chrome [Recommended], Microsoft Edge, Safari *Not compatible with Internet Explorer

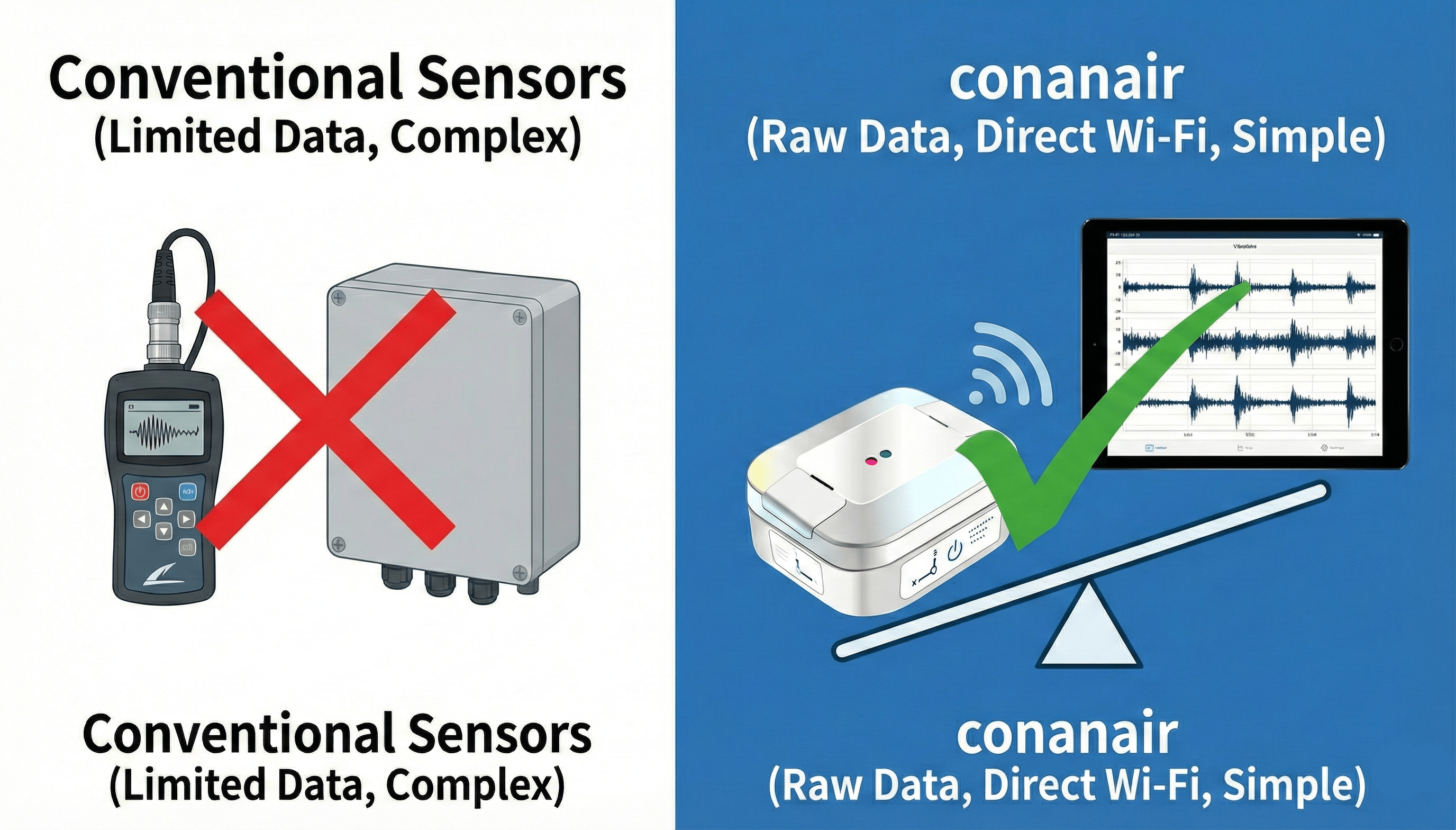

How does “conanair” compare to other products?

With the understanding of what “conanair” is, as a business why should you choose it over other products? Currently, other devices that measure vibration can cost up to $3000, whereas “conanair” being one of the inexpensive choices priced at only a fraction of that. Furthermore, data is always collected in the same format and has two modes: manual and automatic. In manual mode, businesses can measure vibration at many locations as possible and perform patrol measurements conveniently. On the other hand, the automatic mode does not require any additional human force. You can create a schedule to collect vibration data to be uploaded to the cloud of your choice or to your PC through a Wi-Fi access point.

Overall, the compact size, low cost, the two modes, and convenience usage of no additional installment makes “conanair” an easy tool.

The importance of Predictive Maintenance / Preventive Maintenance / Time-based Maintenance / Condition-based Maintenance

Efficient productivity is a goal that every business should aim for. This is significant for business such as manufacturing or a business that deals with mass machinery. Like any human employee, businesses should perform checkups on their machinery similarly to humans. One good way is to create a robust maintenance strategy that is both cost-efficient and effective.

Predictive Maintenance

Predictive Maintenance (PdM) is a process of checking the condition of machinery as it operates to predict which parts are likely to fail. This is done by taking measurements such as machine vibration and plant operating data such as flow, temperature, or pressure. With PdM, large costs of equipment failures or outages can be avoided as businesses will have an advanced warning of a potential problem. Furthermore, businesses can perform replacements on their own schedule.

Examples of Predictive Maintenance

- The refrigerator sensor that alerts the user of any functionality failure.

- Aircraft maintenance where sensors and flight data recorders can predict where irregularities may occur.

Advantage

- Predictive maintenance is planned ahead and can be carried out in a convenient time

- The risk of unexpected breakdowns are reduced

- The equipment life is extended or maintained

- The chances for health, safety, and environmental risks are reduced.

- Businesses will have a better opportunity to understand why equipment failed.

Disadvantage

- The upfront cost including equipment and training is high

When is PdM suitable?

- Have a critical operational function

- Have failure modes that can be cost-effectively predicted with regular monitoring

Preventive Maintenance

Preventive Maintenance (PM) is a type of maintenance that involves a scheduled shutdown of a machine or plant. While the process can cut down failures before they happen but also leads to increased maintenance costs.

Examples of Preventive Maintenance

- Cleaning equipment regularly to minimize dust and dirt

- Repair or replace equipment before failure.

- Lubricate rotating parts to prevent premature wear.

Advantage

- Maintenance is planned on a scheduled basis and helps to prevent unplanned breakdowns.

- The probability of risks leading to catastrophic failures is reduced.

- Businesses will have greater control over inventory.

Disadvantage

- Businesses will have to deal with high replacement costs as certain parts might be replaced too early.

- There might be human error relating to replacement or repair of certain parts.

- There might be parts that have many years of service left but are prematurely replaced.

Time-Based Maintenance

Time-Based Maintenance (TbM), also known as periodic maintenance is a routine based where tasks are performed on an asset at a fixed time interval regardless of its condition. The purpose of TbM is to prevent failures before they happen and improve performance. However, this does not imply a balance between risk and reward, as certain parts might are replaced unnecessarily.

Examples of Time-Based Maintenance

- Tuning up a furnace or heater every year before winter season

- Clearing debris out of a gutter every 6 month

Advantage

- Typically time-based tasks are relatively simple and do not require extensive training to learn.

- Since the long-term cost is low, compared to other maintenance TbM is relatively inexpensive.

- Unlike PdM, no additional equipment or tools are necessary making it easier to implement.

- TbM is effective for continuously running assets since maintenance is scheduled at regular intervals.

Disadvantage

- The main assumption in TbM is that failures are age-related and does not take into account the actual condition of assets. Furthermore, breakdowns and failures do not occur at regular, predictable intervals.

- Frequent scheduling of maintenance might introduce new different risks such as misalignment or incorrect re-assembly.

- Additionally, excessive maintenance might lead to increased cost due to unnecessary downtime, labor, and consumable part costs.

When to use Time-Based maintenance?

Time-based maintenance should be used to prevent failures that are critical to the organization. This can include safety-related activities such as fire alarm inspections because the cost of the asset is high but the cost of the maintenance itself is low.

Condition-Based Maintenance

Condition-Based maintenance (CBM) focuses on preventing asset failures, downtimes, and unnecessary practices by monitoring the asset’s health to determine what maintenance needs to be completed and when. This maintenance is only performed when there are signs indicating a decreasing performance or upcoming failure. In general, condition-based maintenance is done on a needed basis and has the potential to decrease maintenance cost.

Advantage

- There is an increase of uptime and reduced downtime.

- Business will have increased asset life and unplanned failures are reduced or eliminated.

- Business can reduce collateral asset damages and can place greater prioritization and planning of work orders.

- Businesses can increase efficiency in their practices and management.

Disadvantage

- The test equipment to perform condition-based maintenance is expensive to install.

- The probability of detecting fatigue or uniform wear failures are low

Summary

From the list above, Preventive Maintenance is probably the most popular management strategy in the industry. If your business is suffering from unreliable equipment and rising costs related to unplanned replacement, implementing Preventive Maintenance would be a good choice. However, great data management is necessary. (But this will not be a problem if you use “conanair”.)

Case studies

Why should industry apply these monitoring methods?

On average, an average industry will spend around $29k to $47k per hour during downtime. These costs come from revenue losses, recovery costs, and penalty-related fines based on service level regulations or agreements. Furthermore, the average industrial area has 20 to 25 percent of electric motors that are critical to their business. According to the U.S. Department of Energy Office of Industrial Technologies, they estimate that motors represent 60 percent of electrical energy consumption in manufacturing industries, and up to 90 percent in electro-intensive industries. Therefore, with these numbers, being efficient and effective is more important now than ever.

Predictive-Base vs. Condition-Based Maintenance

Both Predictive and Condition Based relies on the usage of sensors. However, Condition-Based only alerts businesses when equipment begins to display problems. On the other hand, predictive maintenance provides data to give business a heads up of repairs or replacements. For a better judgment, it is better for business to not assume that equipment failure occurs only after a fixed period of time in service. According to research done in IEEE, plants that practice predictive-base maintenance have better productivity. The reason is because they have key data that shows businesses more reasons for failure besides time being a factor.

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |