Difference from Time-Based Maintenance (TBM) and Cost Reduction with IoT

Why is preventive maintenance becoming more essential to the market? Optimize your working conditions with maintenance.

Condition-Based Maintenance & Predictive Maintenance

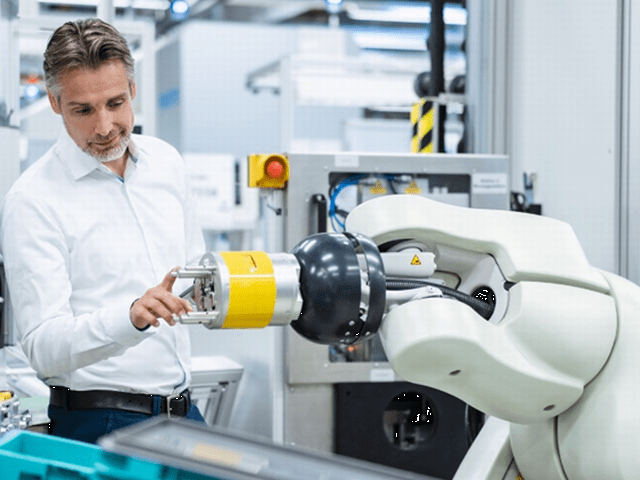

It is more important now than ever for businesses to save money. This can be done by not replacing machines or components unless necessary. Thus, you must monitor its health. This can be done by performing health maintenance. However, this creates another question. How should businesses schedule this maintenance? Usually, these maintenances are performed by specialists or technicians hired by the business. Therefore, businesses cannot perform maintenance without a valid reason. There are methods that businesses can apply to create a maintenance schedule with reasoning. The two methods mentioned here are condition-based maintenance and predictive maintenance.

Condition-Based Maintenance (CBM)

Condition-Based Maintenance is the technique of monitoring the health of a machine or component on a real-time basis through a combination of sensor data such as vibration. The monitoring method is often used as a standalone method. The monitoring can be done remotely but is defined as the process being out of control or in chaos. The three characteristics of Condition-Based Maintenance can be explained as this:

- Sense based : Business should look for smoke or listen to the sound of the machine

- Sporadic Measures : Business should take sporadic measurement on the equipment and compare to previous measurement

- Vibration Analysis Business : Should use control charts to monitor ongoing vibration of the machine or component

Condition-Based Maintenance provides the following type of data

- Diagnostics

- Information and data for Root Cause Analysis and Redesign

- Verification of defect or design correction

- a context embracing all maintenance concepts.

To summarize, Condition-Based Maintenance detects and alerts businesses if the machine starts displaying abnormal behavior.

Here is a basic workflow of condition-based maintenance:

- Determine the baseline standards.

- Install sensors to monitor the conditions.

- Collect and monitor the data.

- Identify conditional data abnormalities.

- Create corrective action work order.

- Perform corrective maintenance.

The History of Condition-Based Maintenance

Sometimes, it is important to know the history behind condition-based maintenance. Here is a brief timeline for condition-based maintenance.

Condition-Based Maintenance 1.0 (1980s and earlier)

In industrial businesses, the usage of condition-based maintenance began with the following indicators:

- Low Tube Oil Pressure

- High Temperature

- Irregular Pump Discharge Pressure

- Low or High Seal Pressure

- Low or High Seal Pot Level

The characteristic of these indicators is that it does not provide businesses with enough time to plan. Thus, businesses would have to develop solutions on the spot. As a result, businesses do not have enough time to line up the right parts, tools, and skills.

Condition-Based Maintenance 2.0 (1990s to 2000s)

Defect detection improvements were made during this period. New factors or indicators were implemented, creating improvement in efficiency in electrical energy and consumption.

However, there were still some challenges left. These indicators did not always bring perfect results. Sometimes it requires third-party opinion as motor current or flow can vary with process conditions.

- Motor Current

- Speed

- Power

- Overall Vibration

- Bearing Temperature

Condition-Based Maintenance 4.0

Currently, we are entering the fourth phase of condition-based maintenance. (If you are wondering about the third movement, it will be discussed later.) While details about this phase are still unclear, the main concept is going digital. The first two phases implemented more of an analog, manual method.

The Examples Of Condition-Based Maintenance

What examples are considered condition-based maintenance? Several techniques that use vibration, sensors, engine oil, or temperature analysis fall under condition-based maintenance. Here is a detailed machine element that can be collected with a sensor.

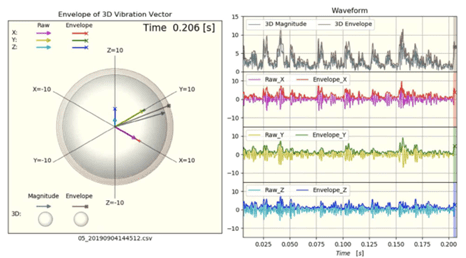

- Vibration and Position ? indicates the dynamic and static motion of the machine.

- Rotor Speed ? the machine vibration frequencies, the important part of analyzing vibration data determining machine malfunctions.

- Temperature: measure the machine’s temperature to see out-of-the-ordinary behavior

- Operating Process Sensor

For example, instead of creating a monthly oil change, a business that applies condition-based maintenance will perform an oil change based on the gauge readings of the monitor oil particles.

Predictive Maintenance

Characteristics of Predictive Maintenance

Predictive Maintenance is a maintenance type in which machines or components are provided maintenance and care on a proactive basis. One of the keywords is “predict.” This allows businesses to be prepared or anticipate any issues with machines or components that can occur and schedule maintenance accordingly.

- The utilization of data history : Predictive Maintenance takes advantage of data history and searches for patterns accordingly then it schedules maintenance. The usage of technology to address potential problems and schedule corrective maintenance before failure occurs.

- Focuses on the early detection : Predictive Maintenance centers around early detection of problems in advance. Using new technology and data history allows for 60 to 90 day advanced detection.

The following failures can be detected

- Lubrication Defects

- Bearing Defects

- Cavitation

- Pump Seal Failure

The workflow of Predictive Maintenance is the following

- Determine equipment and failure mode to be monitored.

- Establish frequency.

- Monitor condition.

- Issue report.

- Is there an abnormality? If not, return to Step 3. If yes, continue to Step 6.

- Create a work order.

- Plan a work date.

- Ensure parts and labor are available.

- Perform repair.

- Close work order and return to Step 3

The History of Predictive Maintenance (Condition-Based Maintenance 3.0)

Recall that in section 2.2.3, condition-based maintenance jumped from 2.0 to 4.0 skipping 3.0. There is a reason for that. Many people believe that Condition-Based Maintenance 3.0 is Predictive Maintenance. The concept that rose during this period in businesses is “leading versus lagging.” In this case, Predictive Maintenance is the leading case as it notifies business ahead of time.

Starting in 2010, the attention to Predictive Maintenance grew because of the advancement in technology such as Artificial Intelligence (AI) and the Internet Of Things (IoT). Using these advanced tools allowed businesses to predict different kinds of failures. This was significant because most industry studies agree that lubrication is 50 to 80 percent cause of failure with rotating assets. Alerts provided by vibration or temperature detection methods from Condition-Based Maintenance were either too late or difficult to establish alerts.

The Examples Of Predictive Maintenance

Examples of Predictive Maintenance can be broken down into four categories

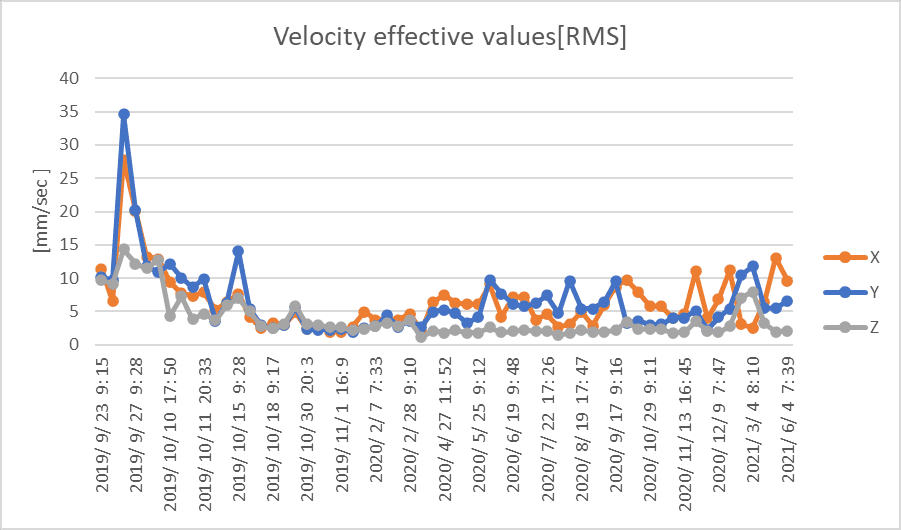

- Vibration Analysis : This is the process of monitoring the level and patterns of vibration signals within a component, machinery, or structure to evaluate the overall condition of the test object.

- Sonic Acoustical Analysis : This is the process of monitoring the sound waves caused by components or machines. The term was commonly used in the music recording industry, but its application in monitoring bearing lubrication is relatively new.

- Ultrasonic Acoustic Analysis : This is the measurement of the interaction of infrared radiation with the matter by absorption, emission, or reflection. This is used to study and identify chemical substances or functional groups in solid, liquid, or gaseous forms.

- Infrared Analysis : This is the measurement of the interaction of infrared radiation with the matter by absorption, emission, or reflection. This is used to study and identify chemical substances or functional groups in solid, liquid, or gaseous forms.

The following applications are suitable for predictive maintenance

- Have a critical operational function

- Have failure modes that can be cost-effectively predicted with regular monitoring

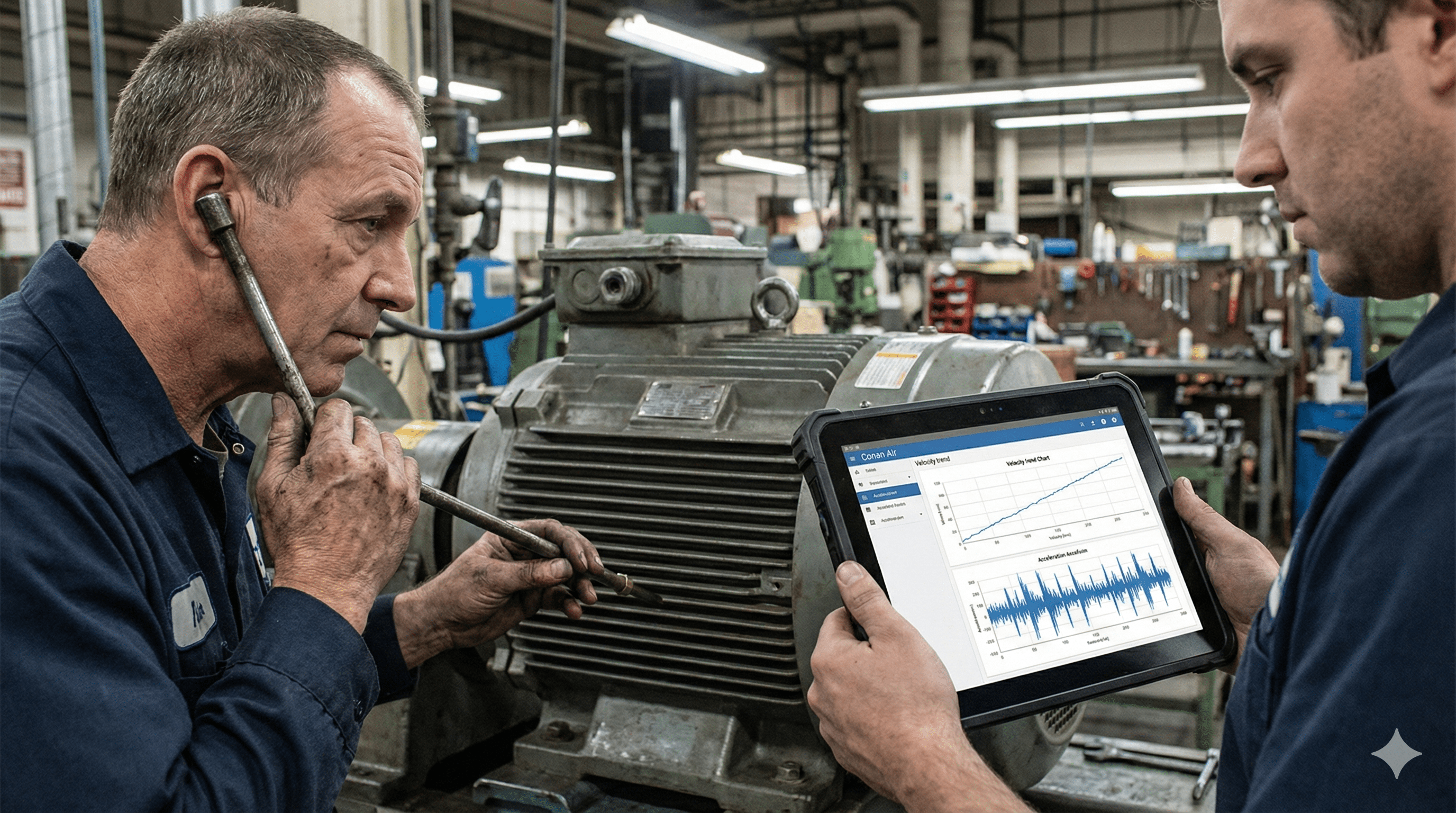

An application example of Predictive Maintenance is attaching a vibration meter to a centrifugal pump motor in a coral preparation plant. The pump is a vital asset, therefore, it is important to prevent unnecessary downtime.

Comparison Between Condition and Predictive

After learning about Condition Based and Predictive Based Maintenance, it is important to know the key differences between them.

|

Condition Based Maintenance

Some type relies on data |

Predictive Maintenance

All relies on data with advanced statistical method |

The advantage comparison between the two

A brief summary of the differences between the two

The advantage of Condition-Based Maintenance

The benefits for businesses for using condition-based maintenance includes the following:

- Business can monitor their machine or components in real time : Condition-Based Maintenance techniques provide data as the machine goes and notifies the business as abnormal behavior occurs.

- Business can expect minimized maintenance expense : Most of the time when people hear the word expense it is usually in terms of maintenance. However, expense in this case includes many other things. For instance, extra downtime will be required for production to halt.

- Business can create a safer work environment. : Most of the time accidents occur due to careless mistakes or actions. These careless mistakes include not being aware of how the machines are operating.

- Businesses can synchronously take care of different parts and multiple machines and address all known problems. : This connects to the previous point, where businesses can create a safe environment. Sometimes, it is challenging to take care of multiple things at once. For example, taking care of five children as a single parent is not an easy task (Not claiming that it will be easy with a double parent.). Applying Condition-Based Maintenance can provide businesses to be aware of the conditions of their machines.

- Businesses can expect to improve equipment reliability.

The advantage of Predictive Maintenance

On the other hand, what are the advantages of using Predictive Maintenance? Here is a list of them.

- Businesses can avoid over maintenance of machines or components : Recall that Condition-Based Maintenance alerts businesses on a real-time basis. This may cause sudden panic that businesses “have to” replace immediately. On the other hand, Predictive Maintenance alerts businesses beforehand. This creates a less stressful schedule for businesses to plan accordingly.

- Minimized sudden asset breakdown : Since Predictive Maintenance alerts on a prior rather than real-time basis, businesses can schedule downtime. This is important for factories where creating parts is an important part of their businesses.

- Increased lifespan of the specific machine or component : Predictive Maintenance allows businesses to predict issues. In most cases, businesses are alerted about issues before it becomes any worse. This implies that businesses can fix the machine or component itself without replacing it entirely. Fixing components will cost money but is cheaper compared to replacing them entirely.

- Continuous machine or component monitoring : Predictive Maintenance does not require additional machine downtime compared to Condition-Based Maintenance. Since the method uses data from the previous recording

The disadvantage comparison between the two

The disadvantage of Condition-Based Maintenance

- Test equipment for Condition-Based Maintenance is expensive to install and analyzing the databases will cost money.

- There will be an additional cost to train the staff with the appropriate knowledge to analyze data and perform work

Any business equipped with complex equipment will require proper training to run them. As a result, it is important to conduct training. That way employees have the proper knowledge and understanding to use the equipment. Additionally, unlike other maintenance methods, Condition-Based Maintenance requires assets to be inspected and monitored frequently. - Fatigue or uniform wear failures are not easily detected with CBM Measurements

Condition-Based Maintenance alone does not provide reliability. There are some additional tools that need to be installed. Furthermore, it does not prevent failures but just detects them. - There might be cases where the condition sensors may not survive in the operating environment

- May require asset modifications to retrofit the system with sensors

- Unpredictable maintenance periods

As mentioned, Condition-Based Maintenance uses the information of the “present” instead of the past. Sometimes these maintenance periods might occur where businesses cannot schedule in advance. Furthermore, there might be inventory or equipment issues. For instance, the maintenance team might not have the same agreement on the priority of equipment as the business managers.

The disadvantage of Predictive Maintenance

Here are the following drawbacks of using Predictive Maintenance.

- The collected data can be misinterpreted, leading to false maintenance requests.

- The cost of establishing a complete system of Predictive Maintenance may be high.

- Predictive analysis may take contextual information into account, such as equipment age or weather.

- Predictive Maintenance may discourage proactive physical inspection and equipment maintenance.

- Preventative maintenance activities may be triggered by timelines rather than genuine machine condition.

In summary, the main difference between predictive and condition-based maintenance is the timing. Condition-Based Maintenance focuses on real-time conditions, whereas Predictive Maintenance is focused on the early detection of defects 60 to 90 days in advance. In other words, predictive maintenance uses sensor data to anticipate when maintenance is needed. Condition Based alerts businesses when problems begin to display.

Which is better for your business?

The core relationship between Condition-Based Maintenance and Predictive Maintenance is that Condition-Based Maintenance is one of the main components of Predictive Maintenance. However, Predictive Maintenance was more of a “nice to have” concept for businesses. In recent years, businesses have taken advancements to label Condition-Based Maintenance as a “need to have” for businesses.

From a historical context, Condition-Based Maintenance has been used in the following type of applications:

- Business that is more interested in Failure Prediction.

- Business that is more interested in the Bottom Up method.

On the other hand, there are recommendations to use predictive maintenance over condition-based maintenance. The reason is simple.

- While real-time data is nice, from a business financial standpoint, it is not that great.

- Most businesses do not have disposable money and are stuck within a budget.

With predictive maintenance, it provides business early notifications. This makes it easier for businesses to plan financially.

However, as a business, it is important for a business to practice vibration avoidance rather than vibration detection. In most cases, vibration occurs due to abnormal behavior. As the adjective describes, this is something businesses should avoid. The usage of vibration should be kept to find the root cause of failures or issues.

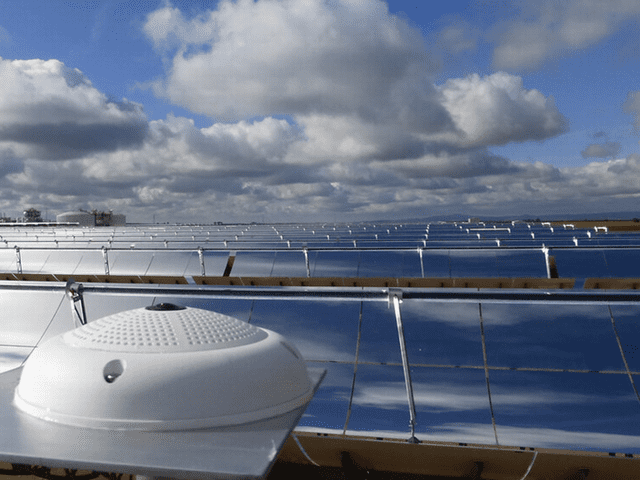

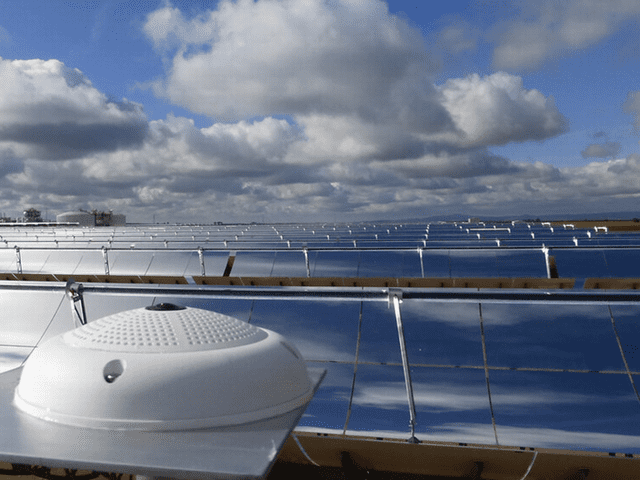

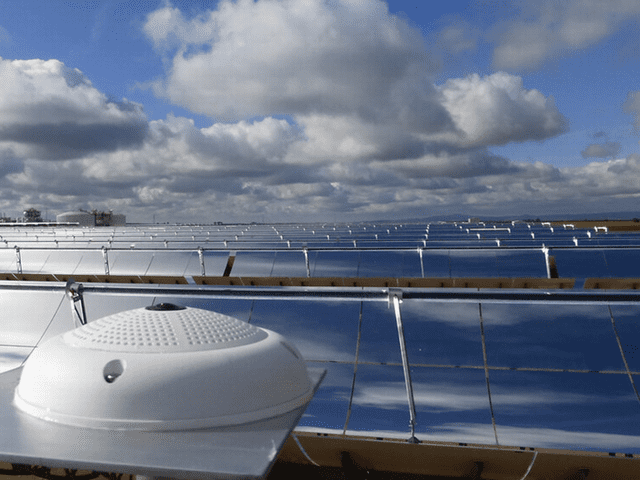

How can my business achieve Condition-Based Maintenance at minimum cost?

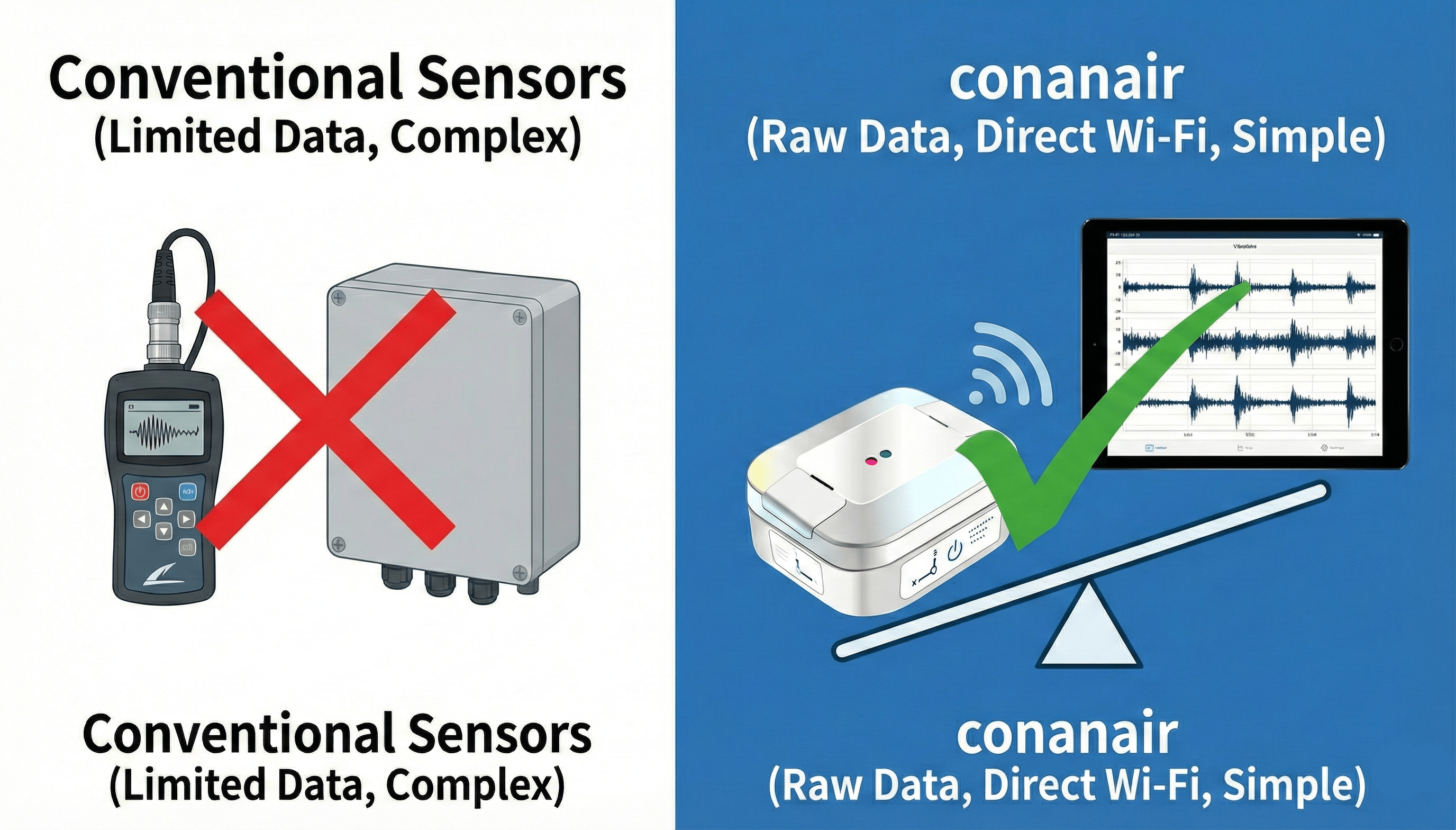

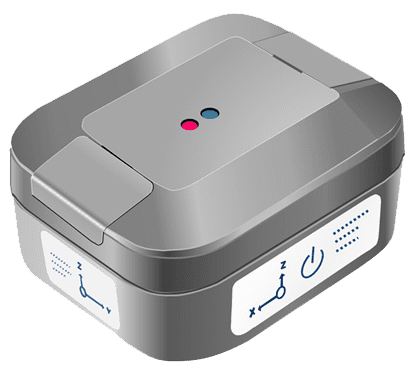

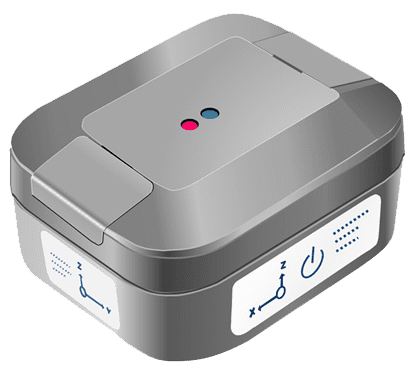

NSXe Co. LTD has released “conanair”, a Wi-Fi vibration sensor that allows companies to detect bearing damage. Businesses can place conanair on the surface of the device. The device collects data on the machine’s performance on a real-time basis, similar to how a doctor performs a physical examination. The device includes inexpensive Micro Electro Mechanical Systems (MEMS), an accelerometer equivalent to the orientation-sensing sensors for smartphones and Wi-Fi modules.

How does conanair achieve predictive maintenance? Recall that predictive maintenance is about providing maintenance to a machine on a specified basis. As explained, conanair takes a real-time measurement of the vibration behavior of the machine. Based on the vibration, it will notify the business if outliers occur.

Conanair can also utilize the collected CSV data as raw data needed by CMMS tools. CMMS tools will become more common in the future, but there are not many devices that can collect raw data, and conanair is an inexpensive and easy way to collect that data. If you are interested in looking at raw data, have been looking for a way to collect raw data, or would like more details, please contact us through the contact form!

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |