Small, Simple, Affordable!

Stop Downtime Before It Starts

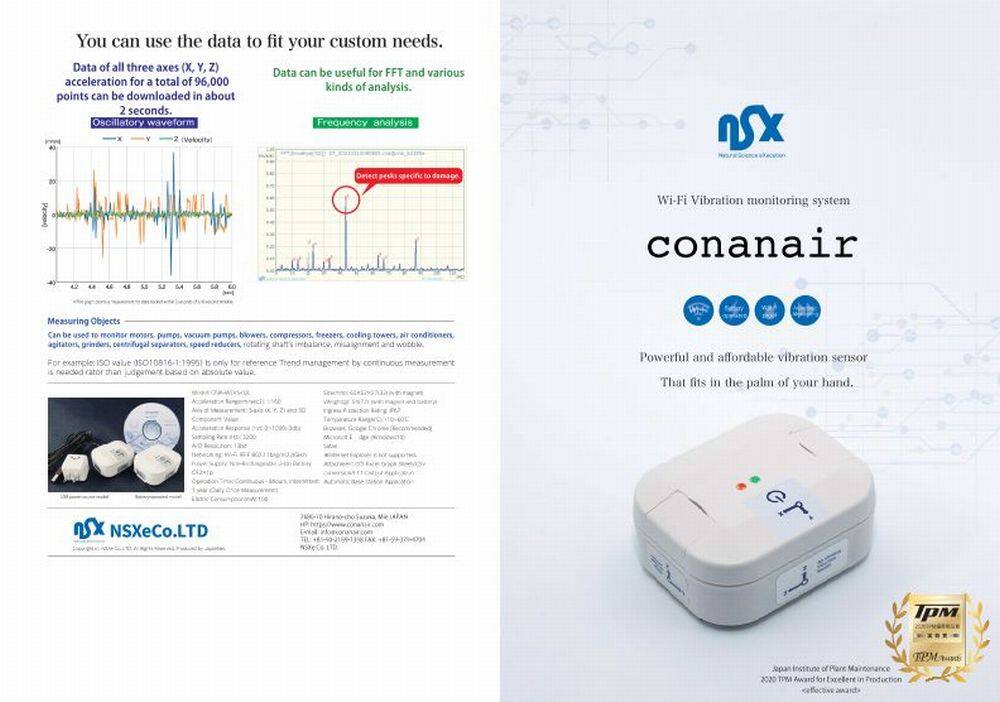

Wi-Fi Vibration Sensor "conanair"

Cumulative shipments have exceeded 2,500 units! (domestic & overseas, as of Oct. 2025)

Used for a variety of equipment maintenance purposes.

![]() Collaborating with NSXe Co. LTD. to develop the O&M Mother business by combining O&M Mother machinery with a NSXe manufactured wireless vibration sensor.

Collaborating with NSXe Co. LTD. to develop the O&M Mother business by combining O&M Mother machinery with a NSXe manufactured wireless vibration sensor.

![]() Press Release of CHIYODA Corporation

Press Release of CHIYODA Corporation

Photos where the Wi-Fi vibration sensor is used : Motor, Pump, Fan, Blower, Compressor, Turbine, Freezers, Air Conditioner, Dust Collector, Conveyor, Screw Extruder, Molding Machine, Roll machine, Reducer, Gearbox, Mixer & etc.

Photos where the Wi-Fi vibration sensor is used : Motor, Pump, Fan, Blower, Compressor, Turbine, Freezers, Air Conditioner, Dust Collector, Conveyor, Screw Extruder, Molding Machine, Roll machine, Reducer, Gearbox, Mixer & etc.

Save money & time for stable machine operation with the affordable Wi-Fi vibration monitoring sensor "conanair" used for predictive maintenance!

Save money & time for stable machine operation with the affordable Wi-Fi vibration monitoring sensor "conanair" used for predictive maintenance!

When will the machine break down? When should the parts be exchanged?

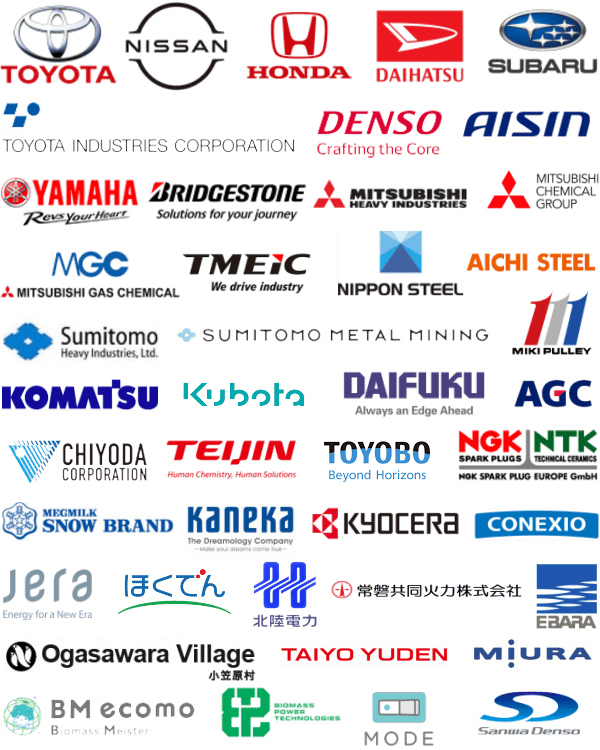

Low cost Wi-Fi vibration sensor "conanair" gauges vibrations from the machine, detecting equipment failures before they happen. By finding the rattling in the motor, it can even detect bearing abnormalities. Explosion-proof models can be used in Zone 1 hazardous areas, including designated plants, factories, and warehouses. conanair streamlines equipment maintenance,

![]() Affordable price & Easy installatio

Affordable price & Easy installatio

It's easy to get started since coananir is wireless and attaches anywhere magnetically, and no application is required. Furthermore, other devices that measure vibration can cost up to $3000, whereas conanair costs only a fraction of that price. Comes with analysis and data-collection software. Powered by readily available batteries. No installation is required, enabling immediate operation.

![]() Saving workers time & Reducing expenses for business

Saving workers time & Reducing expenses for business

It allows your technicians to focus more on planned maintenance tasks. Freeing up time, reducing expenses & having better equipment maintenance. Anyone can perform effective maintenance through simple data management, helping address workforce shortages.

![]() Flexible operation & Utilize data that fits your needs with its flexibility

Flexible operation & Utilize data that fits your needs with its flexibility

You can choose manual or automatic modes. conanair saves raw waveform data. Data can be utilized with many tools and easily integrated with existing or new systems. System integration enables DX and digitalization of maintenance operations, making it easy to build labor-saving maintenance systems using digital twins and generative AI.

We present interviews with two major conanair users:

Japan’s largest power company JERA, and plant engineering leader Chiyoda Corporation. They share why they’ve adopted conanair, the background, benefits, results, and future expectations.

We present interviews with two major conanair users: Japan’s largest power company JERA, and plant engineering leader Chiyoda Corporation. They share why they’ve adopted conanair, the background, benefits, results, and future expectations.

JERA:Improving safety and plant reliability with conanair.

Achieves more frequent remote monitoring, reduces workload, and enhances safety levels.

We provide cost-effective digital-twin services, including 3D measurement of plant equipment and data utilization, enabling virtual visualization of factories. Free demonstration measurements are available to help evaluate usefulness for maintenance tasks. conanair is already integrated with DX and digitalization technologies, enabling labor-saving maintenance systems using digital twins and generative AI. We introduce these systems and use cases.

We provide cost-effective digital-twin services, including 3D measurement of plant equipment and data utilization, enabling virtual visualization of factories. conanair is already integrated with DX and digitalization technologies, enabling labor-saving maintenance systems using digital twins and generative AI. We introduce these systems and use cases.

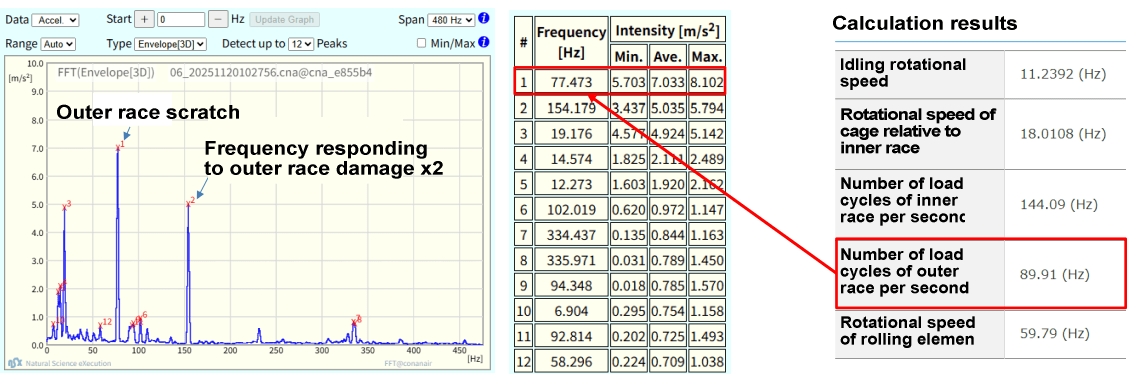

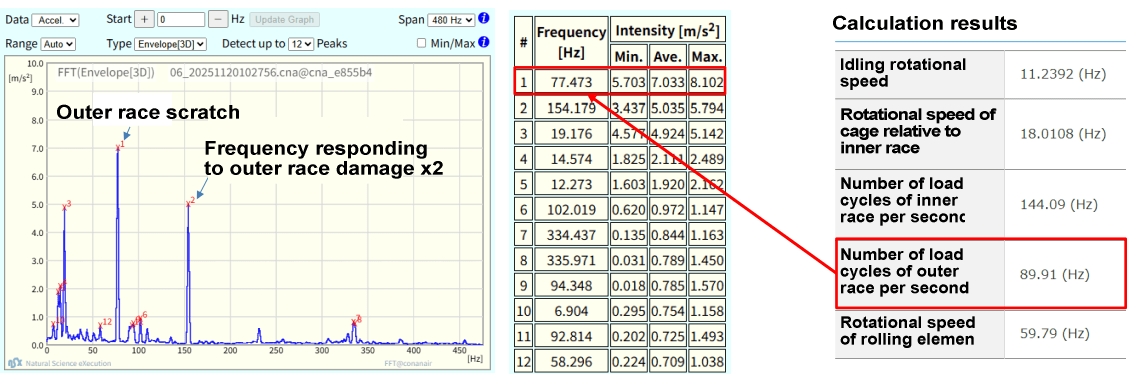

At a wastewater treatment plant in Kurashiki City, Okayama Prefecture, conanair detected bearing damage on a pump motor that showed increased vibration.

![]() Patent Bearing Damage Detection Case Using conanair

Patent Bearing Damage Detection Case Using conanair

Introduce the features of conanair in a video.

Playback time: 1 minute 16 seconds (audio included)

Introduce the features of conanair in a video. Playback time: 1 minute 16 seconds (audio included)

received the excellence award at the 36th small to medium enterprises excellent new technology and new product awards_sp.png)

received the excellence award at the 36th small to medium enterprises excellent new technology and new product awards_sp.png)

conanair (explosion-proof type) received the Excellence Award at the 36th Small to Medium Enterprises Excellent New Technology and New Product Awards. The prize was established in 1988 and is known as the largest in Japan and for selecting only new products and technologies through a rigorous screening process. The explosion-proof type conanair can be used in hazardous areas such as petrochemical plants, fuel-related areas, painting, and powder handling.

The explosion-proof conanair models are certified under international explosion-proof standards ATEX and IECEx, as well as Japan’s domestic JPEx certification. They support flameproof and dust-ignition protection, making them suitable for Zone 1 hazardous areas such as petrochemical plants, fuel facilities, painting operations, and powder-handling environments.

Wi-Fi vibration sensor conanair has received a patent for its technology to detect abnormalities in rolling bearings.

![]() Patent Pending : USA, Germany, India, China

Patent Pending : USA, Germany, India, China

Catalog & material download page. You can download conanair material and related manual and applications from the below page.![]() Material Download

Material Download

IoT stands for "Internet of Things." IoT is related to anyone. It helps people live and work smarter. Find useful information about IoT, vibration sensors, maintenance, monitoring, analysis and detection for beginners, advanced users and experts.![]() IoT Tips

IoT Tips

The information column related to predictive and preventive maintenance systems of factory equipment and machinery, as well as vibration sensors.![]() Columns on Predictive and Preventive Maintenance Systems and Vibration Sensors

Columns on Predictive and Preventive Maintenance Systems and Vibration Sensors

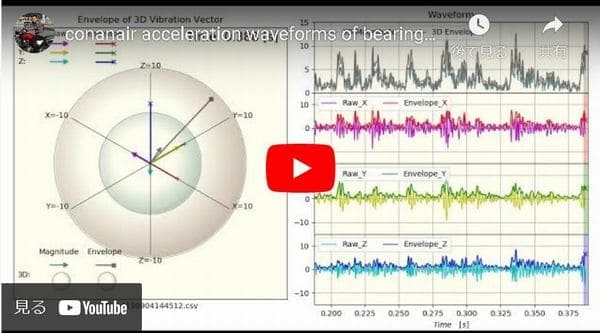

To help you better understand conanair, we present real vibration acceleration waveforms captured by the sensor in our YouTube videos.

![]() Raw Acceleration Waveforms

Raw Acceleration Waveforms

(of bearing N204 in case of outer ring damage)

![]() Raw Acceleration Waveforms

Raw Acceleration Waveforms

(of bearing N204 in case of inner ring damage)

![]() Raw Acceleration Waveforms

Raw Acceleration Waveforms

(of bearing N204 in normal condition at 1200rpm)

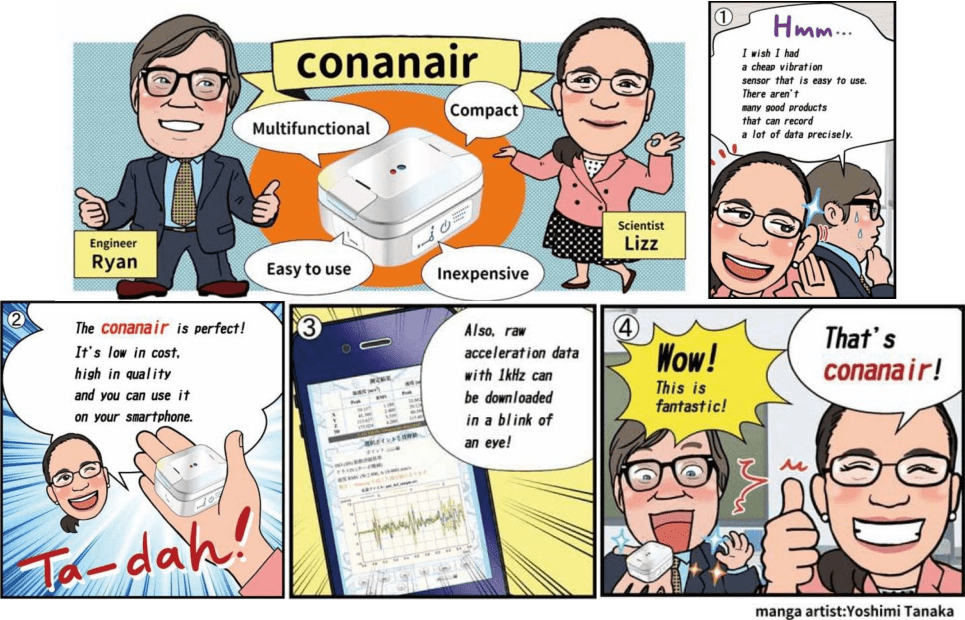

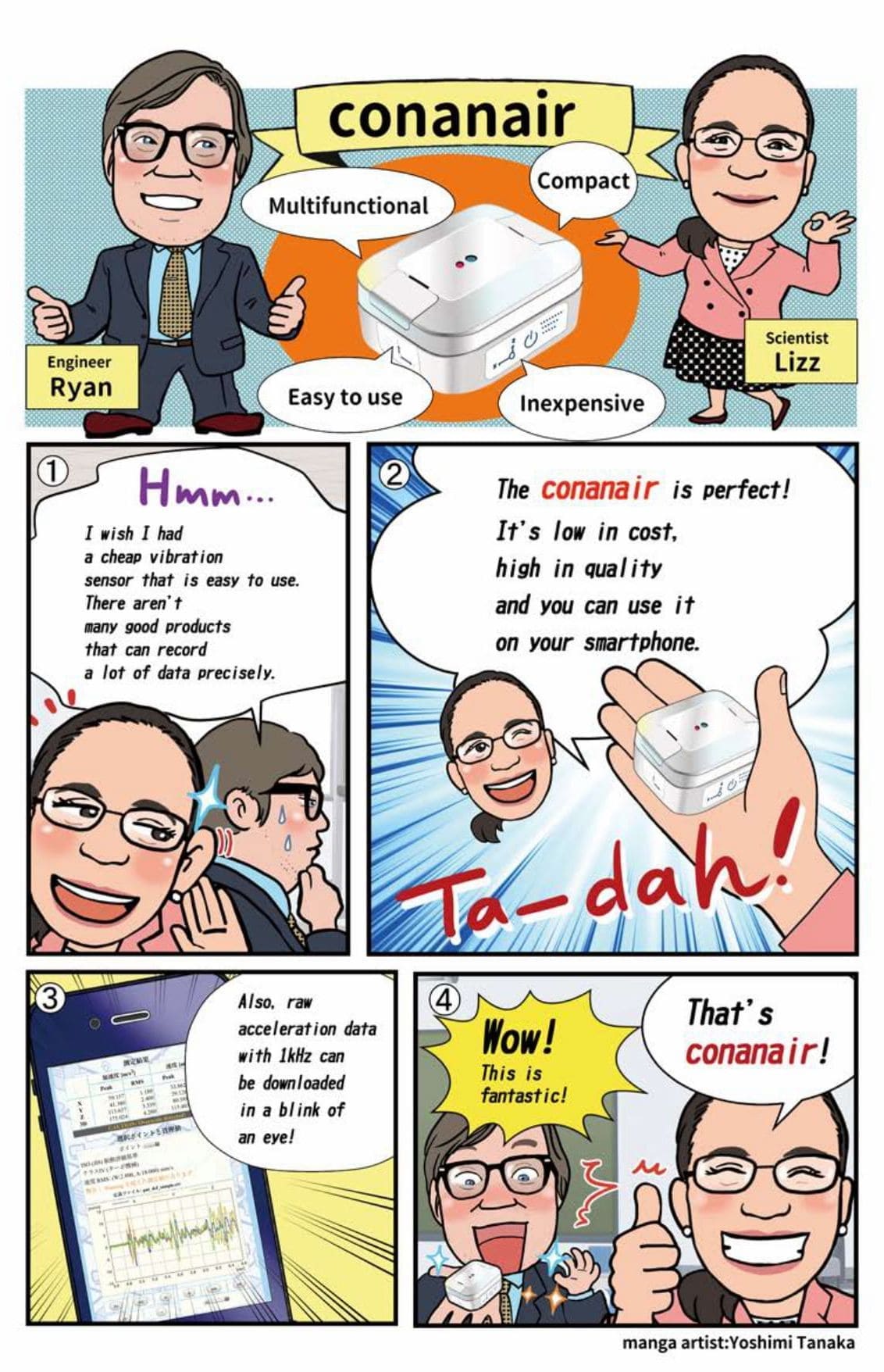

conanair was developed based on real needs from maintenance sites, in collaboration with Dr.Ichiro Koshijima, Nagoya Institute of Technology (Graduate School), and Dr.Yoshihiro Hashimoto, Emeritus Professor at the Manufacturing DX Research Center, Nagoya Institute of Technology. By using familiar devices such as smartphones, PCs, and tablets, conanair is easy for anyone to operate. Combined with commercially available batteries, we developed an affordable sensor with performance essential for predictive maintenance.

Users who have tried Conanair consistently praise it for :

You can experience equipment anomaly detection and predictive maintenance at no cost. Please feel free to contact us for more information.

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Video introduction

Video introduction