Labor-Saving Maintenance Management System Through System Integration

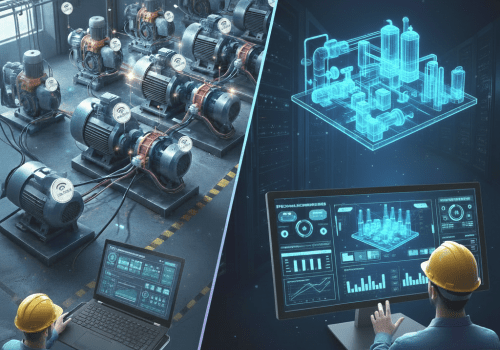

Build a Labor-Saving Maintenance Management System with conanair System Integration

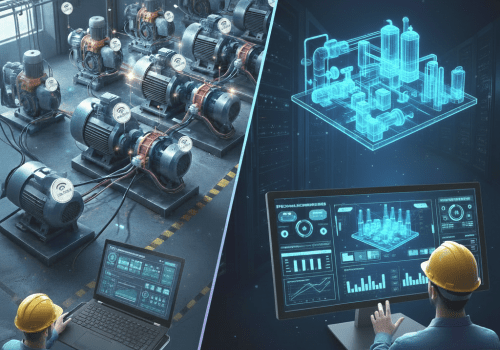

By using generative AI and digital twins with integrating conanair with DX and digital technologies that represent factories in a virtual space, it enables the construction of a labor-saving maintenance management system.

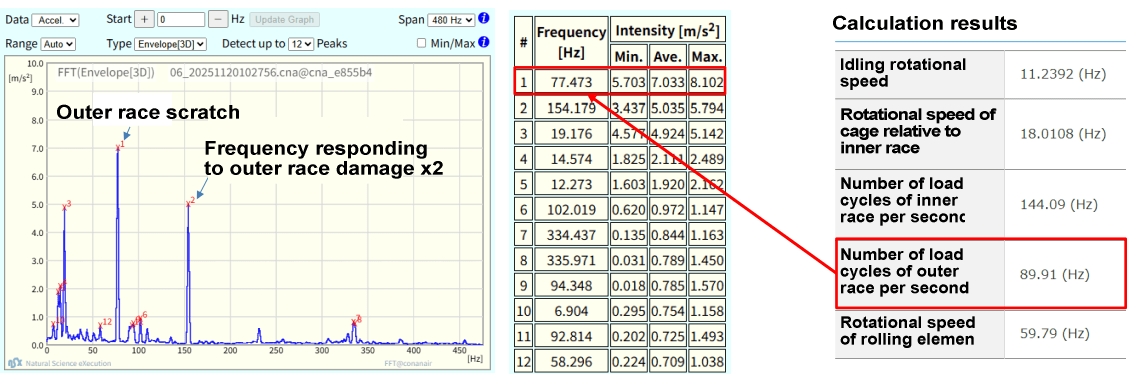

Through integration with visualization systems, automatically collected vibration data from conanair helps reduce inspections that traditionally rely on human senses.

All safety and maintenance management of factory facilities?including equipment, machinery, and piping?can be performed on a PC monitor. This enables predictive maintenance that prevents equipment failures before they occur, while significantly reducing manpower and workload without requiring specialized maintenance skills.

Details of Proposed Technologies and Products

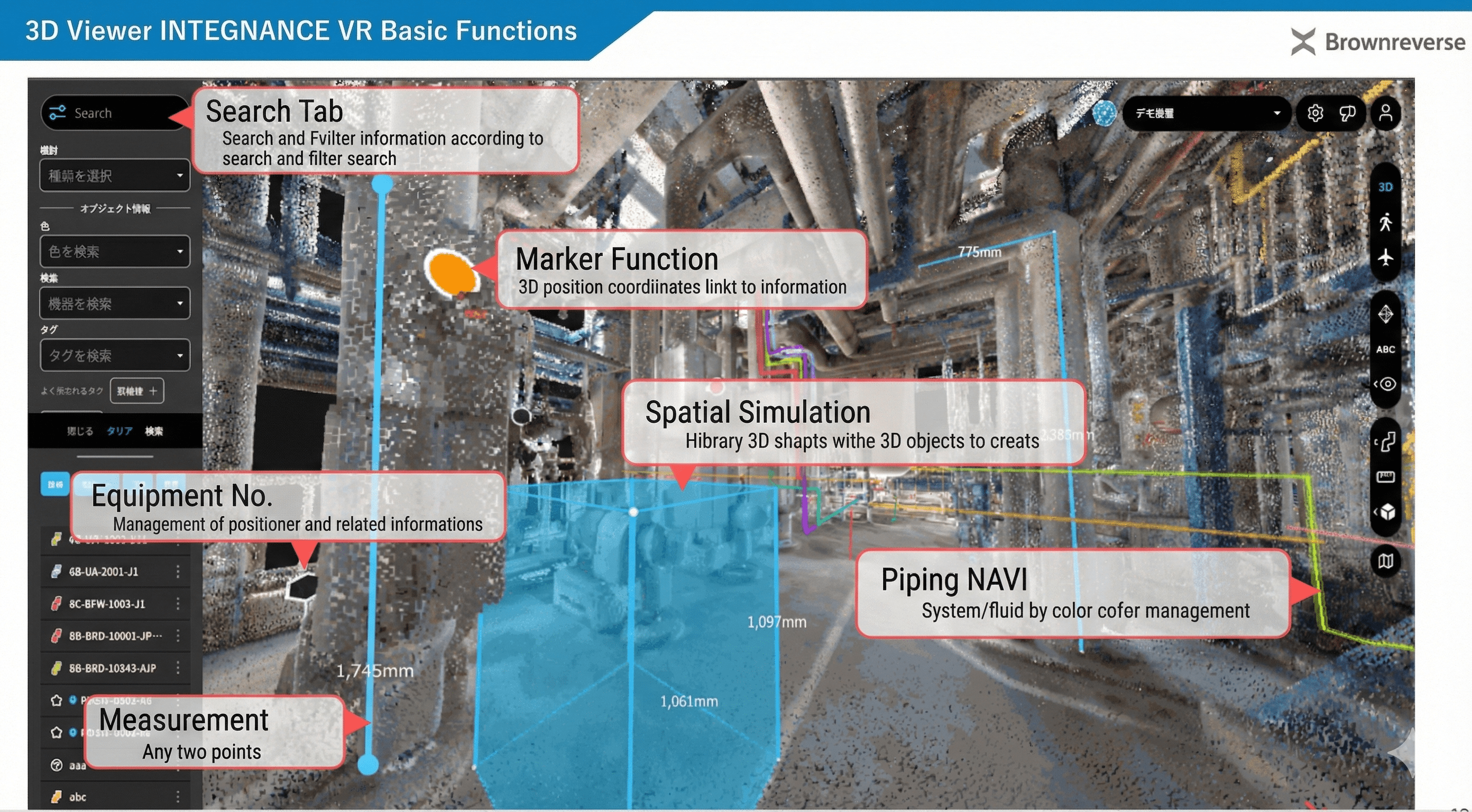

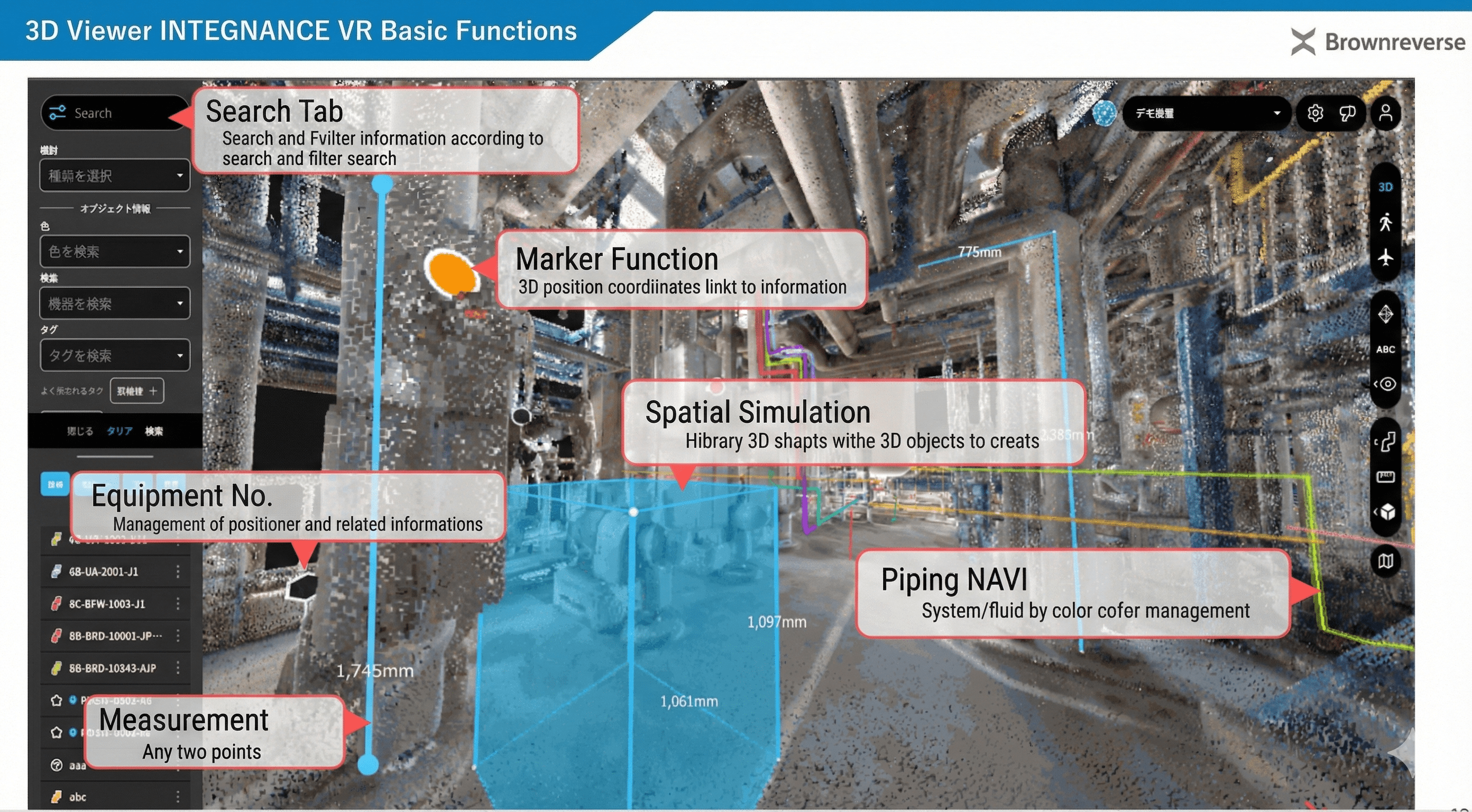

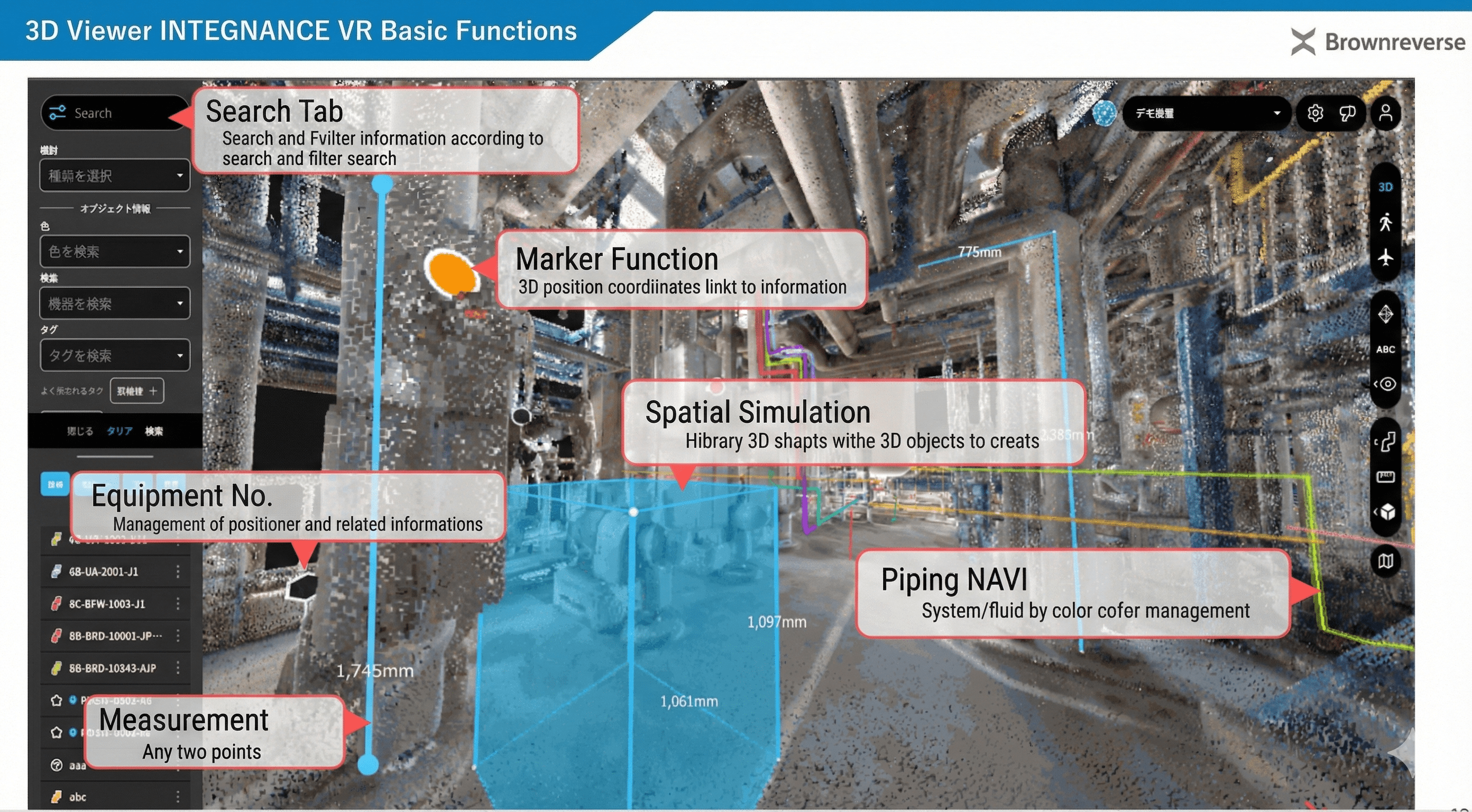

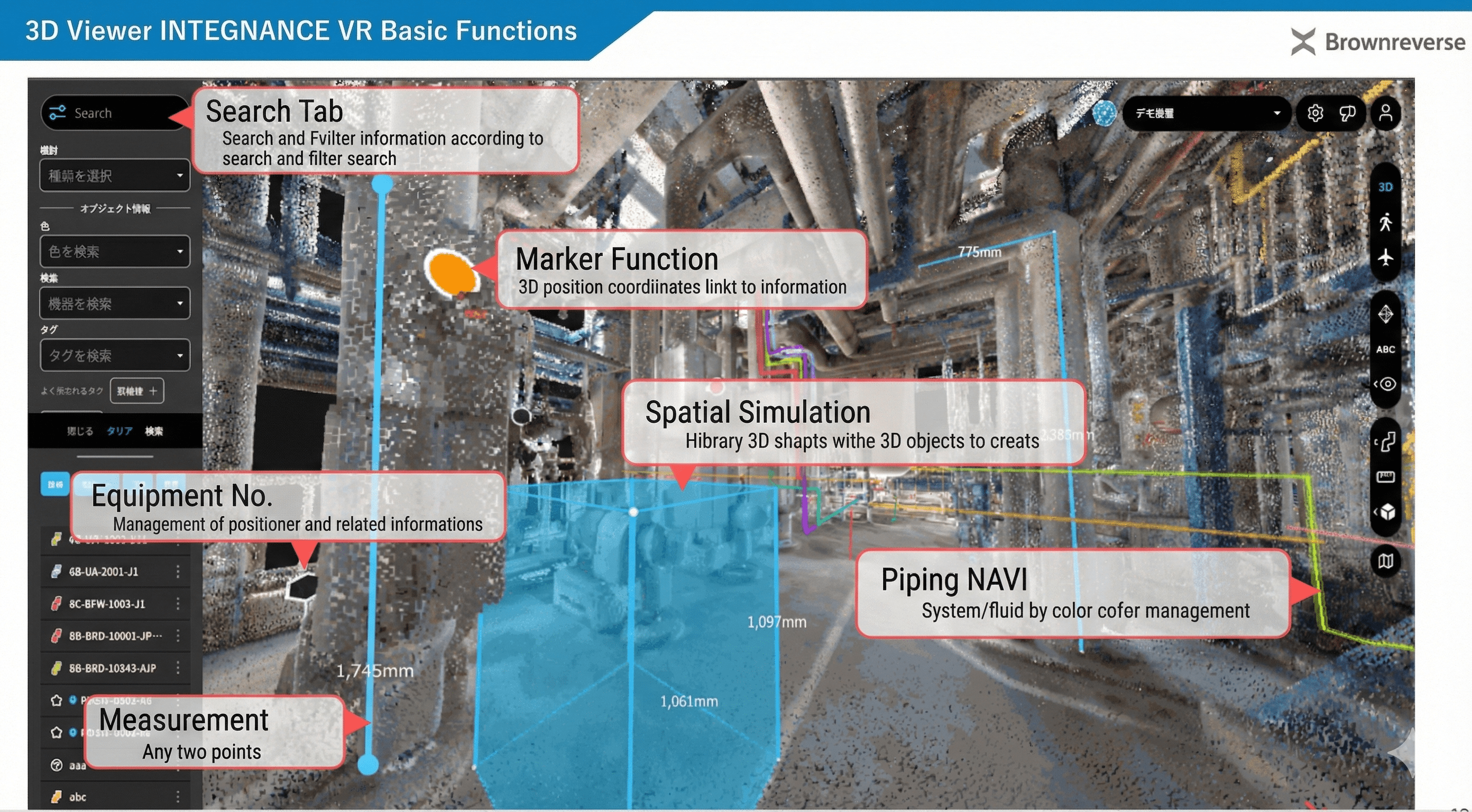

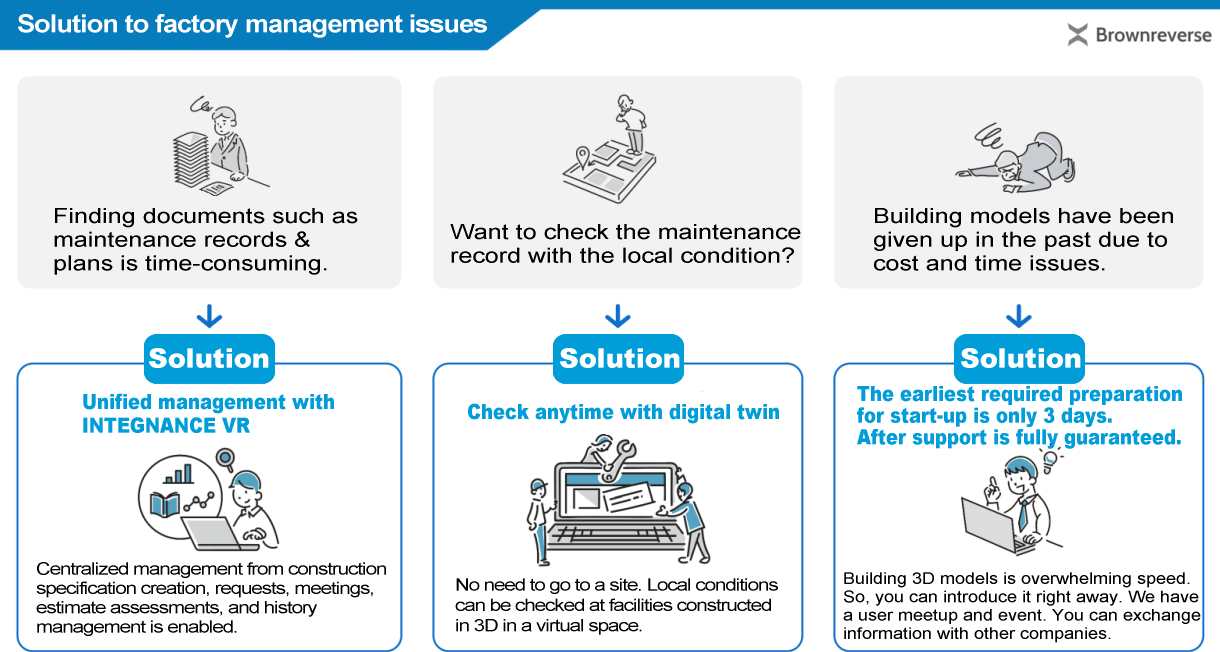

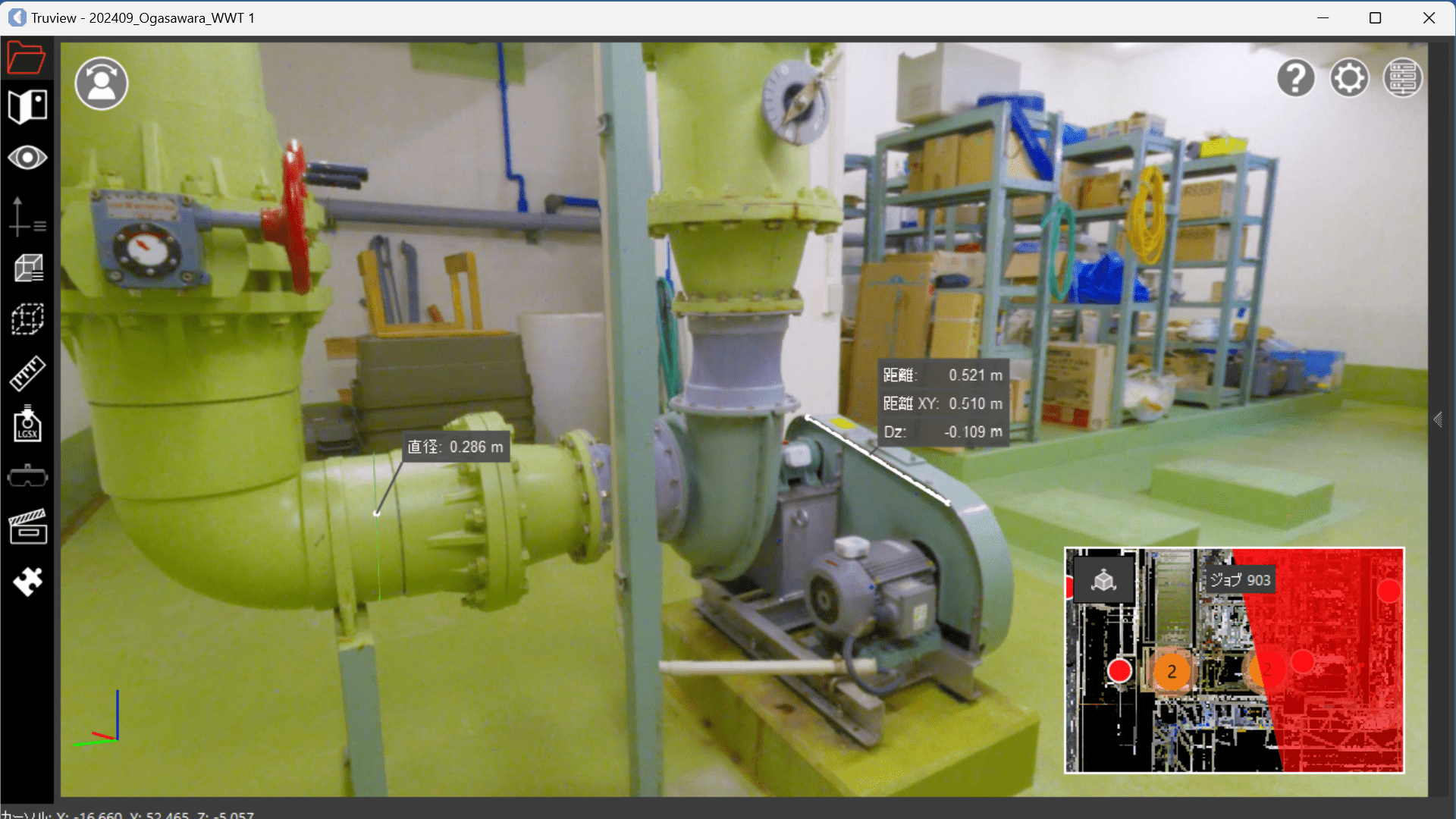

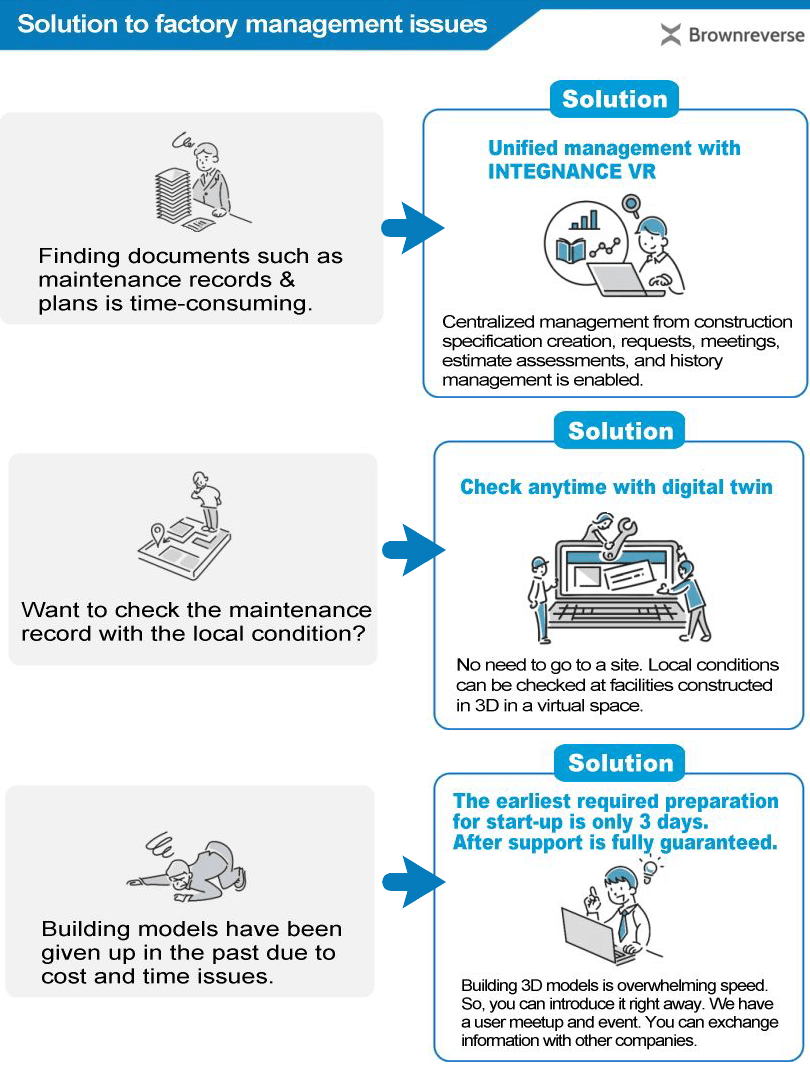

We provide cost-effective digital twin-related services, including 3D measurement of factory equipment and piping, as well as data utilization.

By recreating the site environment on a PC using panoramic images and dimension-based 3D maps instead of conventional drawings or photographs, repeated on-site inspections during maintenance and repair work are no longer necessary.

This allows customers to evaluate whether our solutions are beneficial for their maintenance operations. Using a free PC viewer, users can check dimensional information and piping sizes.

Point cloud data composition and editing are handled by our team, and the 3D point cloud data and panoramic images we provide can be used free of charge on a permanent basis.

Key Features

- High-speed 3D measurement using a compact 3D laser scanner (BLK360 G2), requiring approximately two minutes per measurement location

- Our 3D point cloud data can be rendered and viewed quickly on standard PCs, with no need for high-specification hardware

- The provided 3D point cloud data can also be used with various cloud-based digital twin platforms

- 3D data can be utilized with Tron Inc.’s digital twin solution “Prevu3D,” which is deployed at DENSO

Digital Twin Construction: Labor-Saving Maintenance via Digital Twins & Generative AI

By combining Brownreverse Inc.'s INTEGNANCE VR (which realizes DX and digitalization of maintenance work by representing a factory in a virtual space) and conanair, it converts all equipment, piping, etc., in a plant to 3D data. By integrating Wi-Fi vibration sensors, a labor-saving system in maintenance management can be constructed using digital twins and generative AI.

All maintenance management can be performed on a PC monitor, enabling predictive maintenance to prevent equipment problems before they occur. This eliminates the need for maintenance skills and significantly reduces the personnel and person-hours required. We are a distributor of INTEGNANCE VR.

All maintenance management can be performed on a PC monitor, enabling predictive maintenance to prevent equipment problems before they occur. This eliminates the need for maintenance skills and significantly reduces the personnel and person-hours required. We are a distributor of INTEGNANCE VR.

![]() Go to Details of Digital Twin Construction

Go to Details of Digital Twin Construction

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |