Transforming power plant operations through digital technologies and the development of a vibration sensor born from on-site needs

As voices of Conanair users, we introduce interviews from "Monozukuri no Choujin-tachi / Challenging Conventional Wisdom from the Field."

These interviews feature JERA Co., Inc. and Chiyoda Corporation, discussing their objectives for adopting Conanair and their evaluations of the results after implementation.

JERA Co., Inc.: Japan's largest power generation company, operating across the entire supply chain - from upstream fuel development and procurement to power generation.

Chiyoda Corporation: A global engineering company that designs and delivers energy plants in countries around the world.

Mr. Satoru Iwaoka : Plant Manager, Shin Nagoya Thermal Power Station, JERA Co., Inc.

Purpose and Positioning of the Digital Power Plant (DPP) Project

Overview of People- and Data-Driven Initiatives to Improve Power Plant Safety and Resilience

- JERA Co., Inc. has established a fundamental principle that, as a power generation operator, its highest priority is to enhance the safety and operational resilience of its power plants.

- The Digital Power Plant (DPP) project aims to digitally transform operational activities across JERA's business, which spans the entire value chain from upstream fuel development to power generation.

- By combining human judgment with data-driven maintenance practices, the project is positioned as a smart approach to improving safety and resilience.

- At the same time, the project seeks to enhance the overall reliability of power plants while enabling remote monitoring and operational efficiency through digitalization.

Background and Benefits of Vibration Sensor Deployment at JERA's Shin Nagoya Thermal Power Station

The Path to Adoption Driven by the Lack of Real-Time Data and the Need for Remote Monitoring

- At JERA's Shin Nagoya Thermal Power Station, the direct background for introducing Conanair was the lack of digitized, real-time vibration data and an insufficient number of sensors to enable remote monitoring.

- Traditionally, routine safety monitoring was carried out by operators who regularly visited the site and conducted visual inspections and auditory checks as part of standard operations.

- With the introduction of Conanair, it has become possible to increase the frequency of remote monitoring. This is expected to simultaneously reduce the workload on personnel and enhance safety levels.

- By utilizing Conanair's remotely accessible real-time data, the plant aims to achieve earlier detection of abnormalities and faster response, thereby improving the overall reliability of the power station.

Mr. Toru Yoneyama : Section Leader, Planning & Development Section, O&M-X Solutions Business Department, Chiyoda Corporation

Product Development Driven by On-Site Needs and the Transformation of Power Plant Operations Through Digitalization

How the Efforts of All Stakeholders Come Together to Enhance Power Plant Reliability and Advance Digitalization

- On the power generation side, the DPP project aims to advance equipment maintenance by combining human expertise with data-driven approaches.

- On the sensor supply side, NSXe provides products that enable simple and fast analysis, based on its extensive on-site experience and a strong focus on user-friendly design.

- As an engineering company, Chiyoda Corporation has evaluated and adopted Conanair as part of an integrated solution that brings together physical assets and digital technologies.

- Looking ahead, the partners plan to respond to evolving market needs by developing explosion-proof models and expanding overseas. While maintaining a development approach closely aligned with on-site requirements, they aim to progressively enhance the operational reliability of power plants and further promote digitalization.

Chiyoda Corporation's Adoption of Conanair as Part of a Physical-Digital Integrated Solution

The Role of Conanair in Shaping Chiyoda's New Brand in Plant Design and Construction

- Chiyoda Corporation is an engineering company that undertakes the design, procurement, and construction of large-scale plants on an EPC basis, and has recently launched a new digital solution brand for plant operations.

- This new brand aims to deliver value to operations and maintenance (O&M) through a one-stop approach, providing solutions that combine physical assets (equipment) with digital technologies (data and analytics).

- Conanair has been evaluated as well aligned with our digital strategy, as it enables an easily deployable mechanism for periodically uploading raw vibration data to the cloud.

- Compared with vertically integrated diagnostic systems offered by major vendors, Conanair is better suited to our requirements and is being adopted as a more flexible and user-friendly solution.

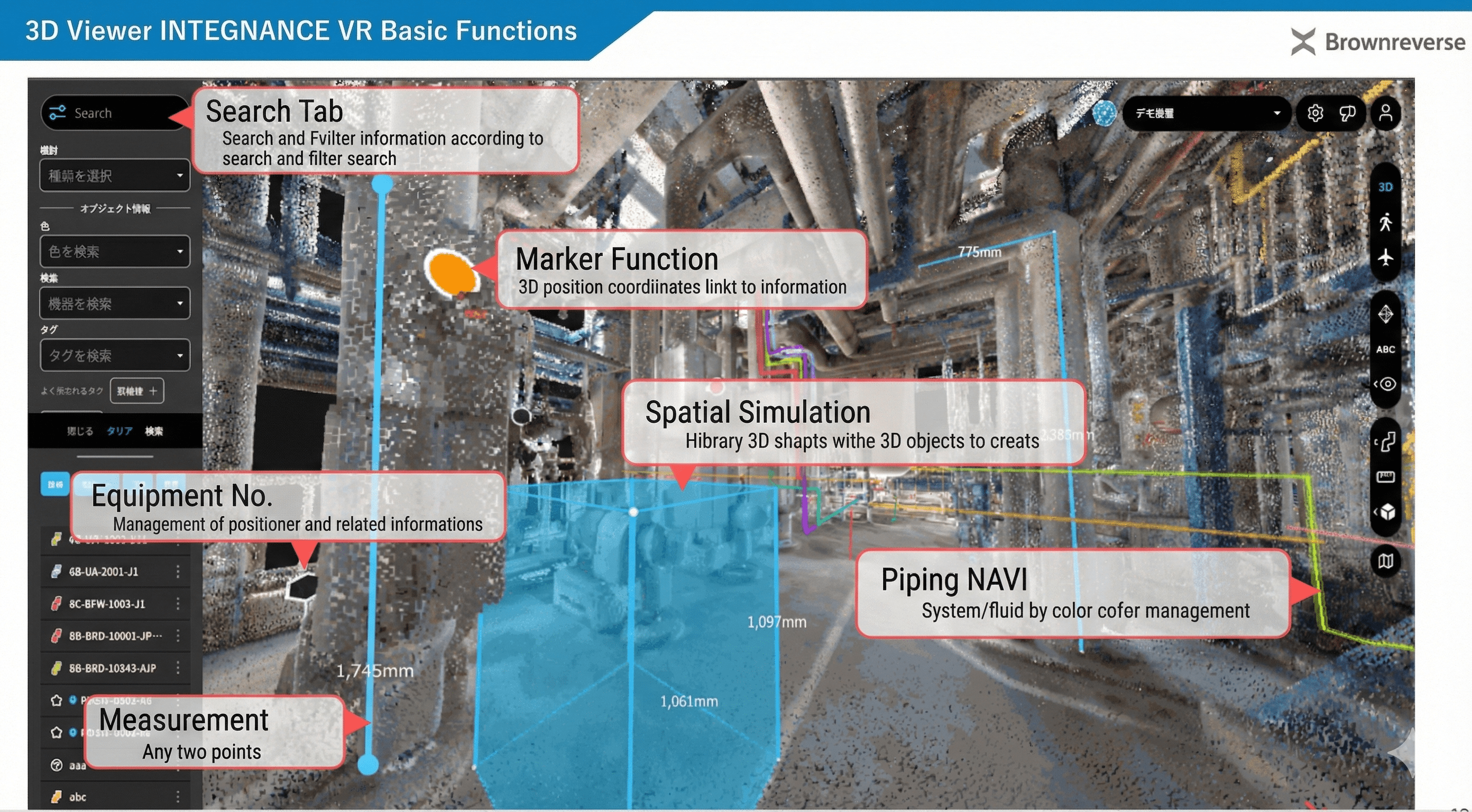

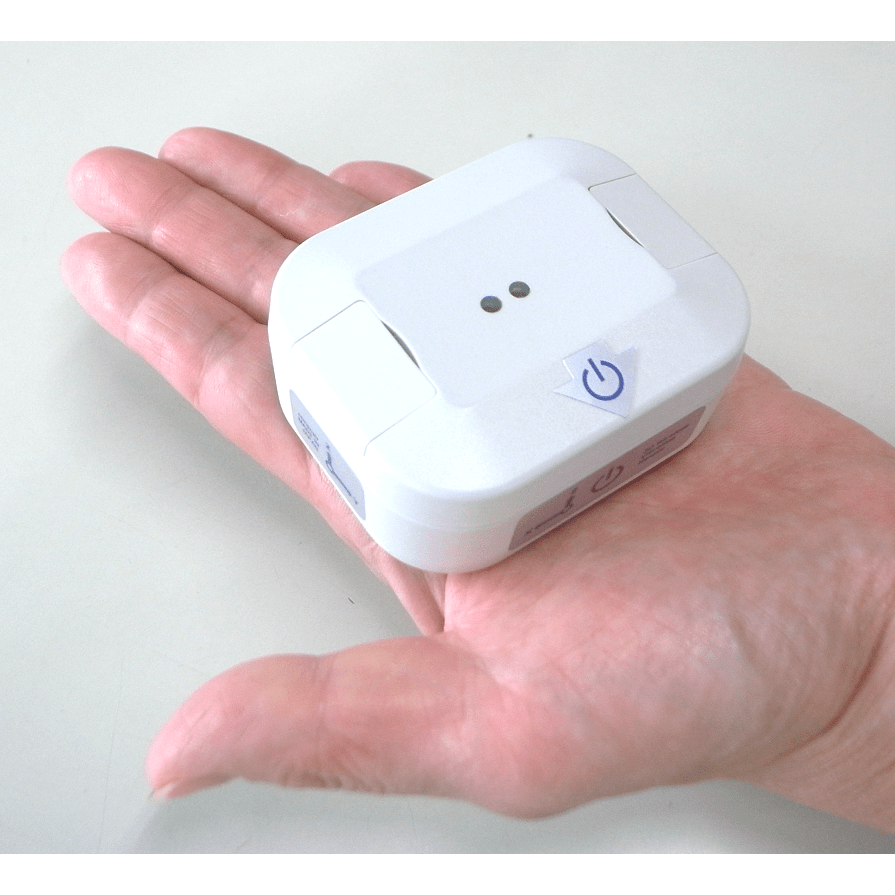

Features and Field Compatibility of the Wi-Fi Vibration Sensor "Conanair"

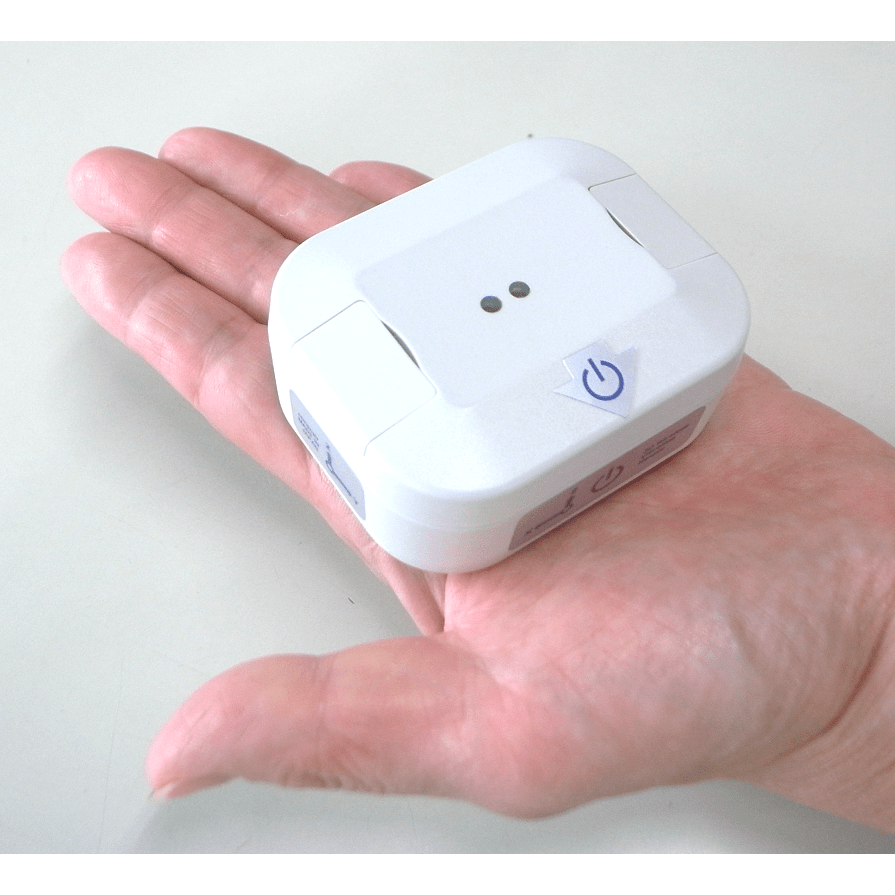

Flexible Deployment Enabled by Magnetic Mounting, Battery Operation, and Wi-Fi Connectivity

- Conanair features a magnetic mounting design that allows it to be easily attached to equipment, reducing installation effort and enabling rapid start of operation.

- Because it is battery-powered, no wiring work or external power supply is required, providing high flexibility in installation locations and allowing deployment at various points throughout the site.

- Conanair adopts a Wi-Fi-based data transmission method, making it easy to build a system that periodically uploads raw data from the site to the cloud.

- These features enable users to quickly begin monitoring equipment that previously lacked vibration sensors, and Conanair has been highly regarded for enabling frequent remote monitoring.

Background of NSXe's Product Development and Business Expansion

The Path to In-House Product Development and a Collaborative Framework

- While supporting customers in production engineering and maintenance operations, NSXe frequently encountered needs related to measurement and process improvement. Drawing on hands-on experience in repairing and maintaining equipment directly at worksites, the company began developing its own measurement and diagnostic devices, placing strong emphasis on the perspective of on-site engineers who actually use the products.

- Along these efforts, NSXe initiated joint development of measurement devices in collaboration with university researchers and other partners. Through these collaborative efforts, the company has consistently translated real on-site needs into practical, field-ready products.

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |