Pump Motor Anomaly Detection at Kurashiki City Waterworks & Wastewater Treatment Plant

We present a case in which bearing damage was detected through verification measurements using conanair on a pump motor whose vibration levels had been increasing at a municipal waterworks and wastewater treatment facility in Kurashiki City.

Pump Motors at Kurashiki City Waterworks and Wastewater Treatment Plant

conanair was selected for Kurashiki City’s Demonstration Experiment Support Program, under which demonstration testing was conducted at the city’s waterworks and wastewater treatment facilities.

Motor Abnormality Detection Based on Vibration (Coupling Side)

Pumps No. 5 through No. 7 are identical models operating within the same system. Among Pumps No. 5 through No. 7, the motor vibration levels of Pumps No. 5 and No. 6 were higher than those of Pump No. 7. For this reason, frequency analysis was conducted using conanair.

The three pumps (No. 5 to No. 7) in the drainage system are the same equipment used for the same purpose.

Since vibration measurements were taken at the same locations on identical equipment, similar values would normally be expected. However, the measured results differed significantly. The following compares vibration levels at the bearing section on the motor coupling side.

Vibration values are expressed in mG (1/1000 of gravitational acceleration).

Measurement period: October 27, 2025 ? November 27, 2025 (one month)

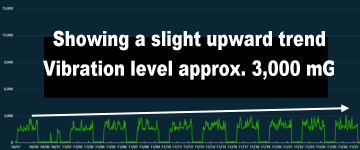

- Pump No. 5 motor: Vibration level approx. 3,000 mG, showing a slight upward trend

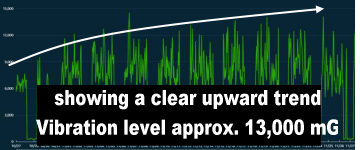

- Pump No. 6 motor: Vibration level approx. 13,000 mG, showing a clear upward trend

- Pump No. 7 motor: Vibration level approx. 1,500 mG, with no upward trend observed

Pump No. 5 motor

Vibration level approx. 3,000 mG, showing a slight upward trend

Pump No. 6 motor

Vibration level approx. 13,000 mG, showing a clear upward trend

Pump No. 7 motor

Vibration level approx. 1,500 mG, with no upward trend observed

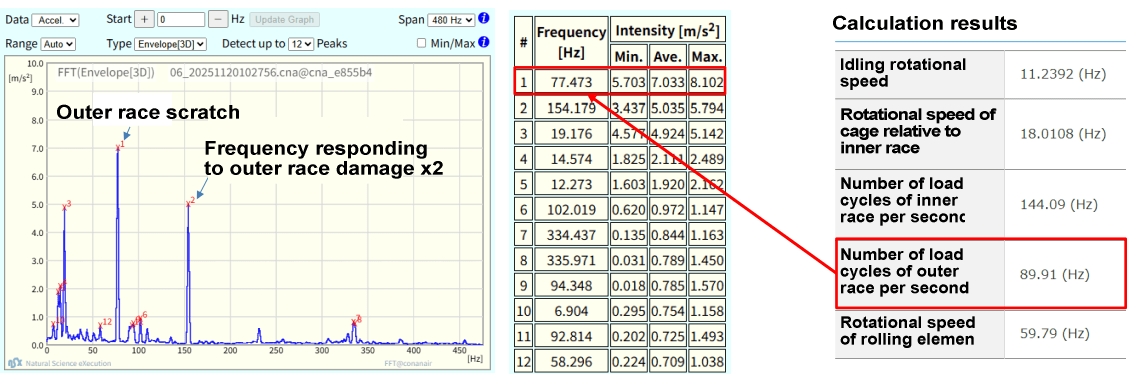

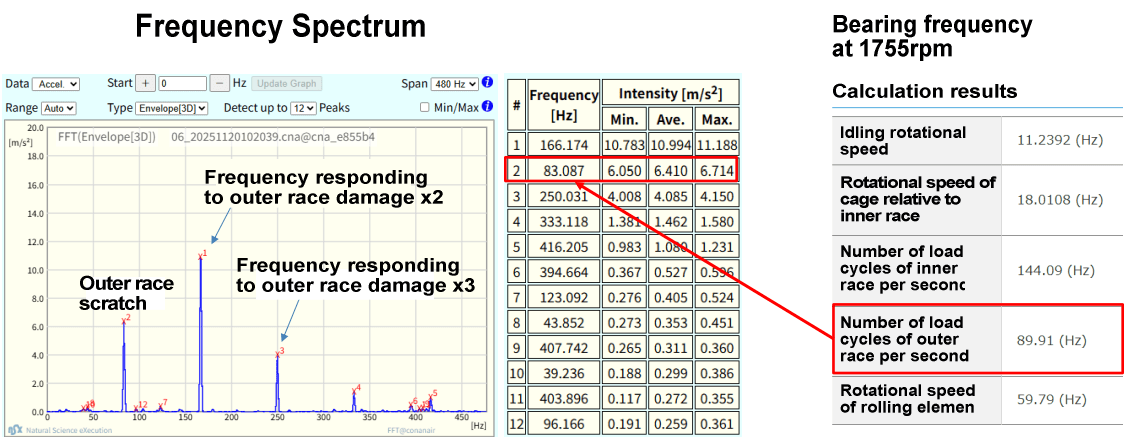

Pump No. 5 Motor (Coupling Side)

- Rotational speed: 1,755 rpm (as listed on motor nameplate)

- Bearing: 6312ZZ (as listed on motor nameplate)

Demonstration test results using conanair

High vibration levels (approx. 12 mm/s2, slightly below) with the presence of an outer race defect frequency were observed, leading to a diagnosis of outer race damage.

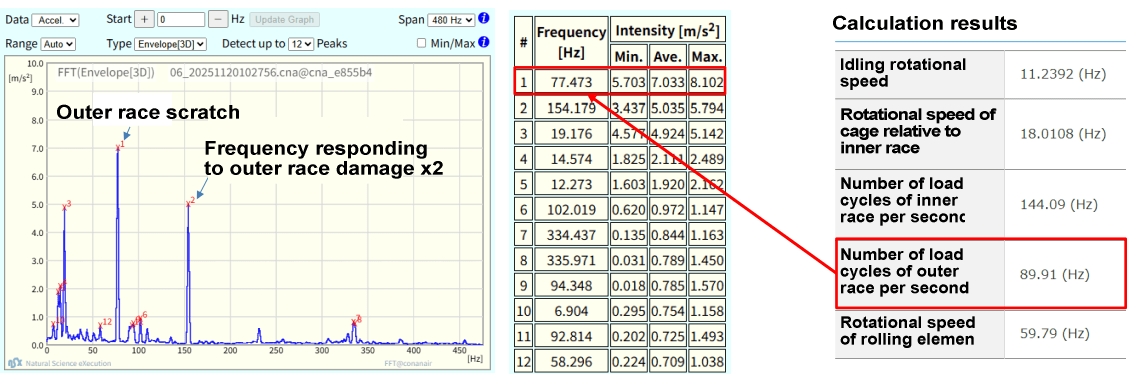

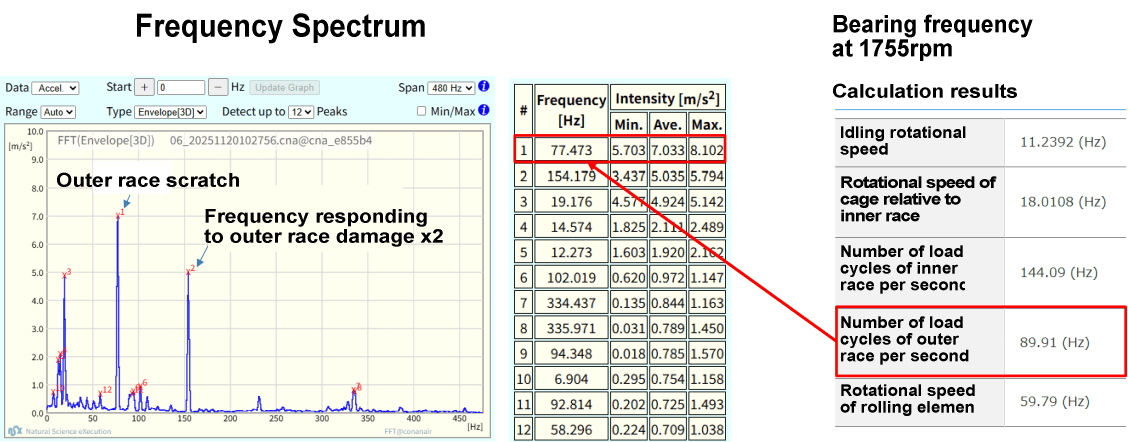

Pump No. 6 Motor (Coupling Side)

- Rotational speed: 1,755 rpm (as listed on motor nameplate)

- Bearing: 6312ZZ (as listed on motor nameplate)

Demonstration test results using conanair

Elevated vibration levels (approx. 7 mm/s2, slightly above) with the presence of an outer race defect frequency were observed, leading to a diagnosis of outer race damage.

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |