No Expertise Needed. 4 Practical Steps from Selection to Installation and Judgment You Can Start Tomorrow

Once you understand the importance and mechanism of predictive maintenance, the next step is implementation.

However, many people wonder, "Which machine should I measure first?" or "Where is the correct place to attach the sensor?"

In this guide, we navigate you through 4 concrete steps, from selecting target equipment to installation tips and anomaly judgment criteria, so you can start today without specialized knowledge.

Air-cooled heat exchanger fan in high location

![[Target Selection] Air-cooled heat exchanger fan in high/inaccessible location (conanair installation recommended)](../img/01.jpg)

- STEP 1: Select Equipment for Monitoring

- STEP 2: Decide Measurement Points (Sensor Installation Position)

- STEP 3: Measure Initial Values (Baseline)

- STEP 4: Set Judgment Criteria (Thresholds) and Monitor Trends

- For Those Who Want to Know More: Utilizing Precision Diagnosis

- Case Study: Automated Monitoring at a Biomass Power Plant

The first step is to catch signs of failure and create a site that doesn't stop. Have you ever experienced noticing a strange noise from a machine only to find it was already too late? "Vibration Trend Monitoring," which grasps the health of equipment numerically, is one of the most effective means for preventing sudden failures (CBM: Predictive Maintenance). Using conanair, we explain the monitoring procedure you can start today without specialized knowledge.

STEP 1: Select Equipment for Monitoring

First, you don't need to put sensors on every machine. Narrow down the targets based on the following priorities:

- Critical Equipment: Machines that, if stopped, halt the entire line and cause significant loss.

- Equipment without Spares: Pumps or fans with no alternatives if they break.

- Equipment in High/Narrow Places: Locations difficult or dangerous for patrol inspections.

General centrifugal pump and motor

![[Installation Position] Secure the sensor with a magnet in a place where vibration from bearings or reducers is easily transmitted](../img/37kw industrial water pump.jpg)

STEP 2: Decide Measurement Points (Sensor Installation Position)

The iron rule is to measure vibration "close to the source and at a location with high rigidity."

- Near Bearings: Install directly on the bearing housing of the motor or pump.

- Measurement Direction: Start with the "radial direction" where vibration is most easily transmitted.

- Installation Method: With conanair, you can easily fix it with a magnet or screws.

Install with magnet where vibration

from bearings/reducers is transmitted

![[Installation Position] Secure the sensor with a magnet in a place where vibration from bearings or reducers is easily transmitted](../img/biomass power plant-chip conveyor motor.jpg)

STEP 3: Measure Initial Values (Baseline)

After installation, acquire data while the machine is operating normally. This becomes the "Standard for a Healthy State (Baseline)." The essence of trend management is not looking at the initial number itself, but "how it has changed compared to usual."

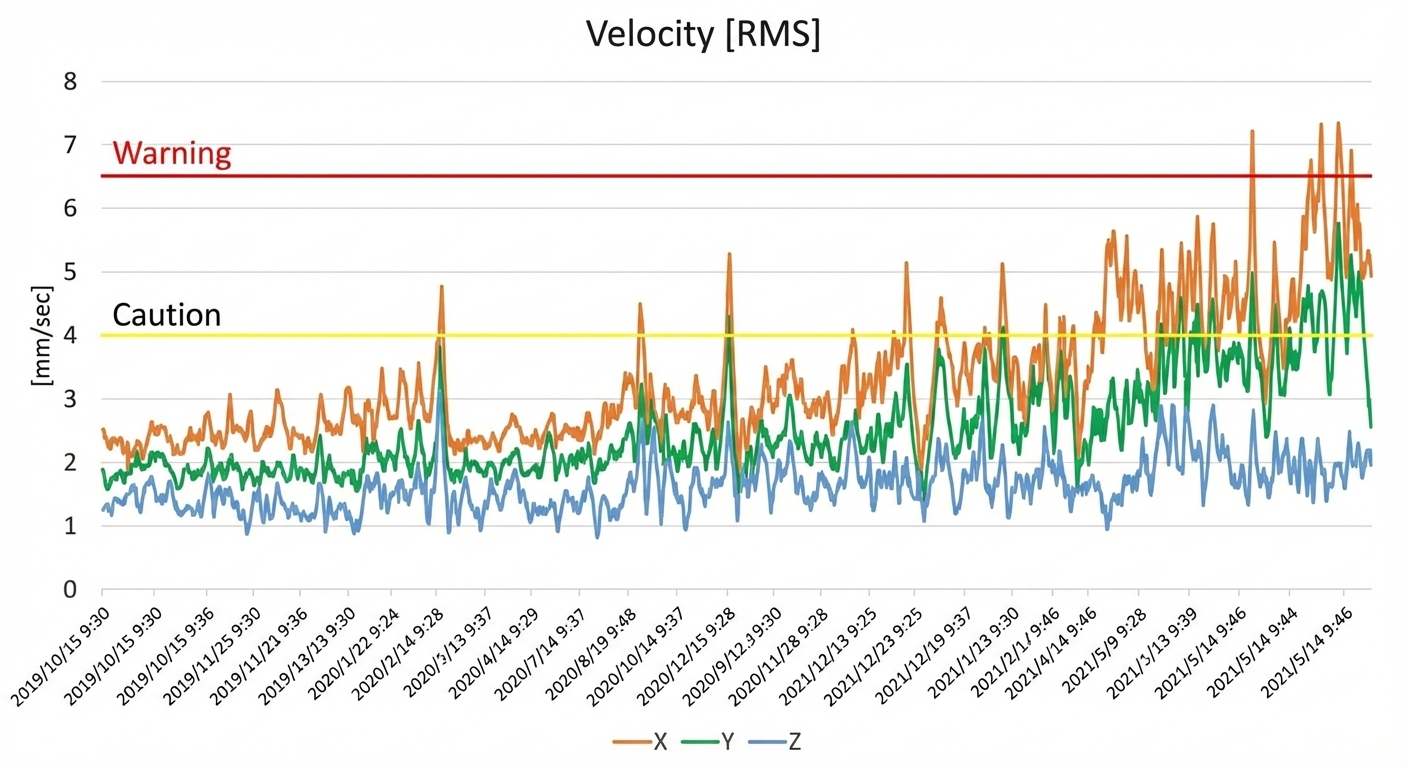

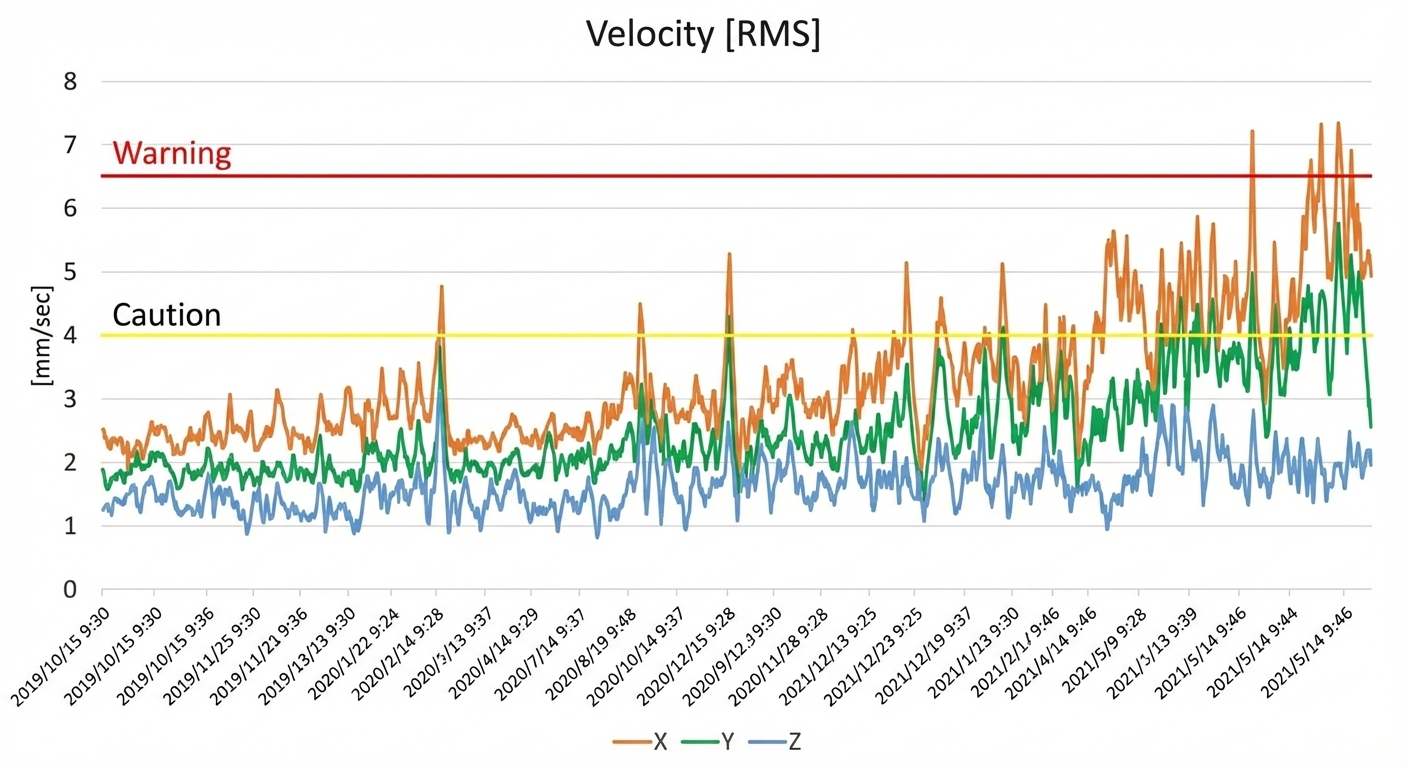

STEP 4: Set Judgment Criteria (Thresholds) and Monitor Trends

Decide the benchmark (threshold) for "how high the number gets before it's dangerous," and check the graph regularly.

- Caution (Yellow): Consider lubrication or tightening at the next periodic inspection.

- Abnormal (Red): Schedule planned shutdown and repair.

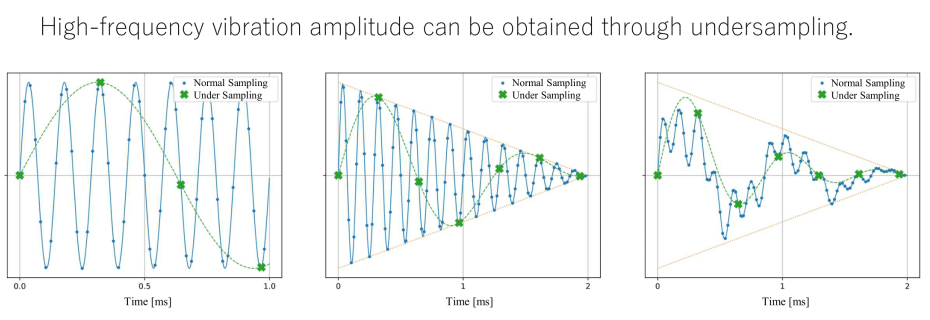

For Those Who Want to Know More: Utilizing Precision Diagnosis

When vibration values increase and signs of "abnormality" appear, performing precision diagnosis via FFT (Frequency Analysis) allows you to identify the specific cause of the anomaly, such as bearing defects, unbalance, or misalignment.![]() Details on precision diagnosis: Anomaly Detection of Machines via Vibration Monitoring

Details on precision diagnosis: Anomaly Detection of Machines via Vibration Monitoring

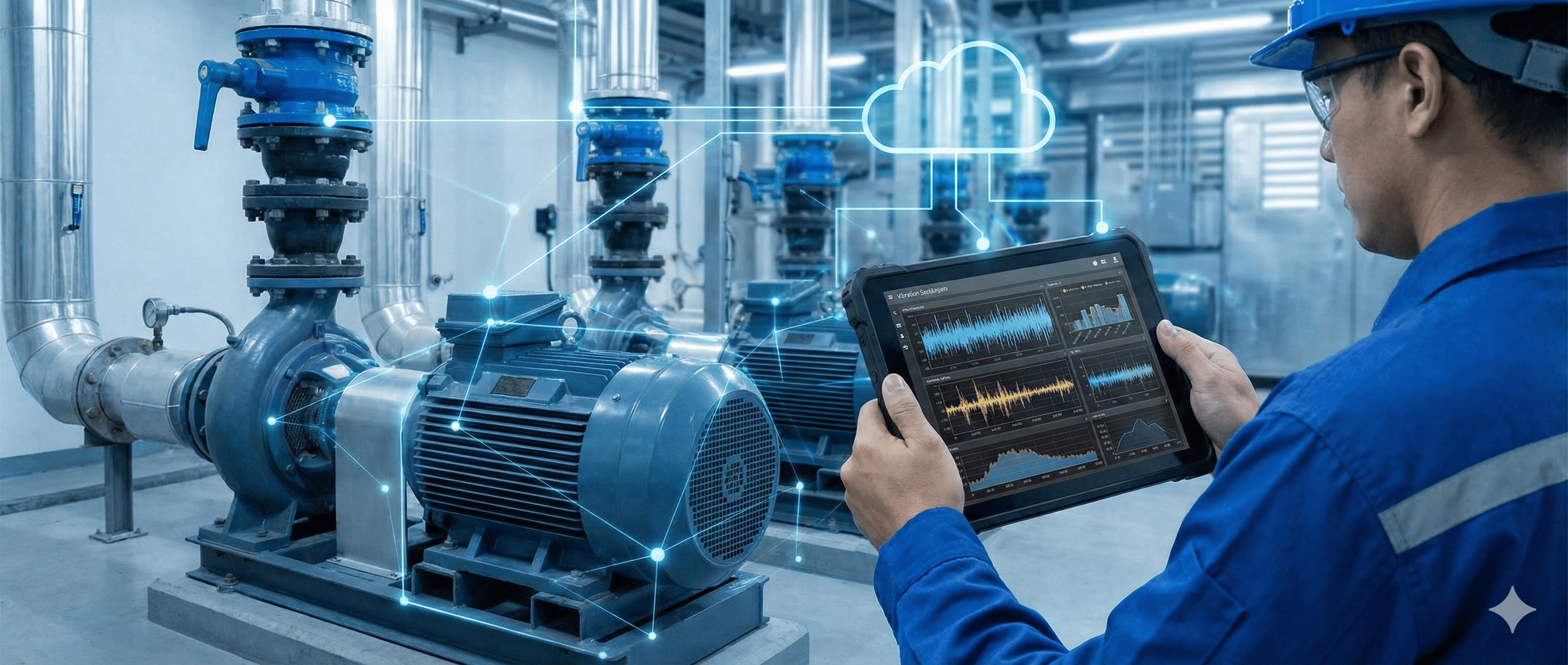

Case Study: Automated Monitoring at a Biomass Power Plant

From Monthly Patrol Inspections to Daily Automatic Monitoring

- Challenge: Inspecting large fans without spares in high places was dangerous, and noticing abnormal sounds tended to be delayed.

- Solution: Installed conanair and checked trends from an office PC.

- Result: Early detection of bearing deterioration from rising vibration values. By performing planned repairs during equipment downtime, we achieved zero sudden operational stoppages.

Why conanair is Chosen for "First-Time Predictive Maintenance"

- Overwhelmingly Low Cost: Can be introduced at a fraction of the cost of traditional systems.

- Wiring-Free Wireless: No complex construction needed. You can install it the day you decide.

- Intuitive Software: Even without specialized knowledge, you can understand the status at a glance with graphs.

Why not start small with just one unit? Please feel free to contact us with requests like "I want to consult on which equipment to start with."

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |