Achieving Ideal Online Monitoring at the Cost of Semi-Online Systems

The traditional approach of "fixing machines only after they break" can no longer prevent sudden line stoppages or substantial repair costs. What is needed on the shop floor today is a shift to "Predictive Maintenance (CBM)," which uses numerical vibration data to prevent failures before they occur.

In this article, we clearly outline the differences between conventional "periodic inspections" and "predictive maintenance," and explain how implementation alleviates the burden on site personnel, covering the fundamental knowledge required.

- 1. The Importance of Predictive Maintenance in Rotating Equipment

- 2. Types and Flow of Equipment Diagnosis: From Screening to Precision Diagnosis

- 3. [Comparison] The Paradigm Shift in Vibration Monitoring Methods

- 4. Why Can conanair Overturn "Common Sense"?

- 5. Conclusion: The "Smart" Choice for the Labor Shortage Era

1. The Importance of Predictive Maintenance in Rotating Equipment

Rotating equipment such as motors, pumps, and fans are the heart of a factory. With recent labor shortages and the decline in skilled maintenance personnel, reactive maintenance ("fix it when it breaks") can no longer prevent the risk of sudden line stoppages. This is why "Predictive Maintenance" is gaining attention. By continuously monitoring equipment "vibration" and catching signs of failure early, it becomes possible to achieve both maintenance cost reduction and stable operation.

2. Types and Flow of Equipment Diagnosis: From Screening to Precision Diagnosis

To perform efficient maintenance, the following two-step process is standard practice.

Step 1: Screening (Simple Diagnosis)

For all equipment, check whether the vibration magnitude (RMS value) exceeds a set threshold to determine if an anomaly exists.

Step 2: Precision Diagnosis (Root Cause Identification)

For equipment where an anomaly was found in Step 1, perform Frequency Analysis (FFT) to identify the cause, such as "bearing damage" or "unbalance."

The conanair Advantage:

Typically, inexpensive sensors can only handle Step 1. However, conanair can acquire "raw waveform data," allowing a single device to cover everything up to Precision Diagnosis.

3. [Comparison] The Paradigm Shift in Vibration Monitoring Methods

Until now, there has been a "common sense" belief that "Cost" and "Precision" in vibration monitoring are in a trade-off relationship where you cannot have both.

| Monitoring Method | Traditional Wisdom | The World conanair Realizes |

|---|---|---|

| Offline Monitoring (Patrol Inspection) |

Low cost but high risk. Manual inspections face challenges with human oversight and labor shortages. |

Automation of Inspection Eliminates patrol effort and removes human error through high-frequency measurement. |

| Semi-Online Monitoring (Wireless/Periodic) |

Optimal cost-performance. Wireless sensors measure periodically; accumulated data is collected via patrol. (Current mainstream) |

Continuous monitoring at low cost. Enables advanced monitoring within a semi-online budget. |

| Online Monitoring (Continuous/Wired) |

High function but high price. Wiring work and system setup cost millions of yen; limited to critical assets. |

【Shattering the Norm】 Achieves online monitoring at semi-online prices. Collects raw vibration waveforms for precision diagnosis. |

| Method | Traditional Wisdom | The World conanair Realizes |

|---|---|---|

| Offline (Patrol) |

Low cost but high risk. Manual inspection issues. |

Automation of Inspection Eliminates human error. |

| Semi- Online (Wireless) |

Optimal cost-performance. Current mainstream method. |

Continuous monitoring at low cost. Advanced monitoring within budget. |

| Online (Wired) |

High function, high price. Limited to critical assets. |

【Shattering the Norm】 Online monitoring at semi-online prices. |

Question the status quo. Online monitoring is no longer expensive.

To companies that have compromised with semi-online monitoring (periodic measurement) prioritizing "cost-performance": conanair uses proprietary technology leveraging existing Wi-Fi infrastructure to realize ideal online monitoring (continuous, automatic) at the implementation cost of a semi-online system.

4. Why Can conanair Overturn "Common Sense"?

- Zero Construction Costs: Maximizing Wi-Fi Infrastructure

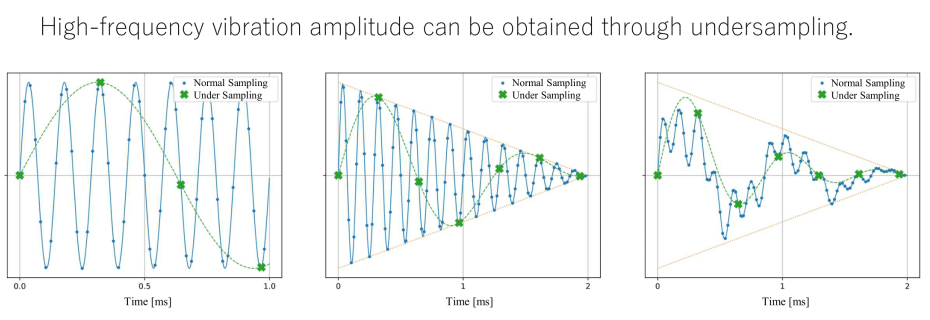

Expensive communication wiring and dedicated receivers are unnecessary. Simply ride on the Wi-Fi network already present (or cheaply built) in your factory, and all equipment goes "online" instantly. - Balancing "Low Cost and High Performance" with Patented Technology

Through proprietary patented technology (such as Under-Sampling), we reliably capture the high-frequency components necessary for detecting minute bearing anomalies while keeping device costs low. - Mobile Integration for the Front Lines

Not just monitoring from the office, but the ability to hold a smartphone over a machine on-site and instantly check raw waveforms. This "mobility" is a strength that traditional, expensive, rigid online systems lacked.

5. Conclusion: The "Smart" Choice for the Labor Shortage Era

Manual inspections have limits. Yet, investing millions in every piece of equipment is not feasible.

"Semi-online cost, Online value."

This new standard is the correct answer for the future of manufacturing DX.

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |