The Core of Bearing Diagnosis Without Expensive Vibration Meters, Realized by "Undersampling"

"Inexpensive sensors cannot detect fine bearing anomalies." Conanair's proprietary "undersampling" technology rewrites this conventional wisdom. How did we achieve diagnostics comparable to expensive precision vibration meters with a palm-sized sensor? We will explain the surprising mechanism that holds the key: the "active utilization of aliasing noise," complete with diagrams.

Conanair's undersampling technology challenges the assumption that only high-frequency response vibration meters can detect bearing anomalies. We explain the technical background of how it captures impact vibrations reaching several kHz despite using a low sampling rate.

1. Conventional Method: High-Frequency Sampling and Envelope Processing

![[Conventional Method] Measurement image of internal bearing shock vibration (2-8kHz) via high-speed sampling](../img/bearing diagnosis - conventional method-eng.png)

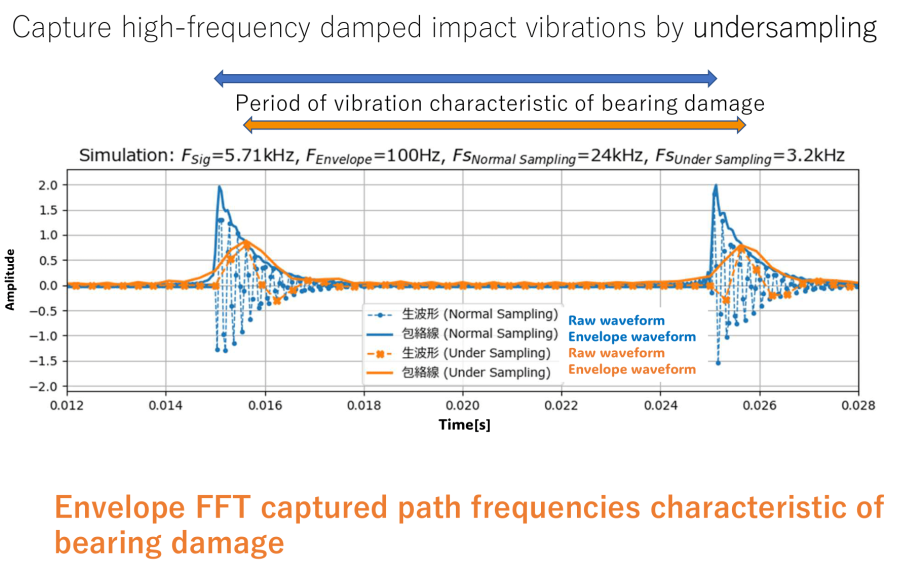

When a bearing is damaged, "shock damped vibration (high-frequency range of 2kHz?8kHz)" occurs when metal components make contact.

High-Precision Measurement to Capture Shock Damped Vibration (High Frequency)

To capture this, generally, high-speed sampling such as 10kHz to 20kHz is required based on the Nyquist theorem.

Identifying the Damaged Area

The damage location is identified by cross-referencing the shock occurrence cycle with "bearing defect frequencies" calculated from the bearing structure (number of rolling elements, inner/outer ring diameters) and rotation speed.

Why is Envelope Processing Necessary?

Even if you perform frequency analysis (FFT) directly on the high-frequency raw waveform, the shock cycle (low-frequency component) does not become visible. Therefore, the standard diagnostic method is to perform "absolute value processing + envelope processing" to extract the shock occurrence interval before performing FFT.

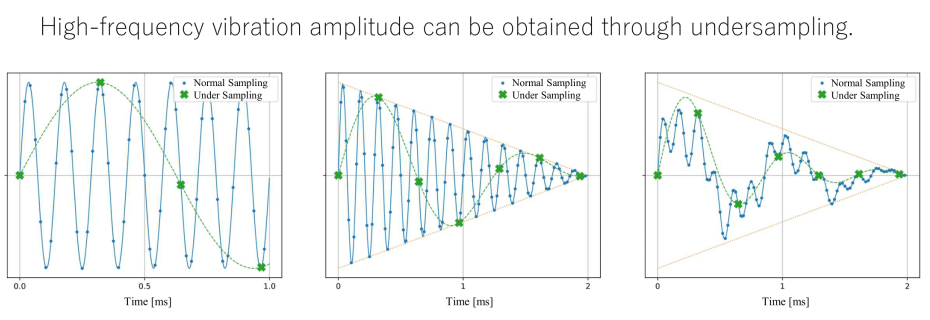

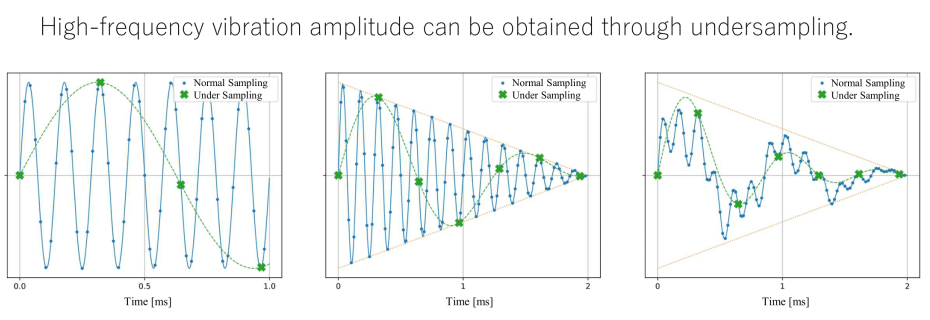

2. Conanair's Proprietary Technology: Active Utilization of Aliasing Noise

![[Conanair] Mechanism where high-frequency components are recorded in the low-frequency band due to undersampling](../img/undersampling-eng.png)

Standard vibration sensors are equipped with an "anti-aliasing filter (LPF)" that removes components above 1/2 the sampling frequency. Without this, "aliasing noise" occurs, where high frequencies appear transformed into low frequencies, distorting the waveform. However, conanair deliberately chose the method of "capturing aliasing noise without applying a filter."

Why We Deliberately Omitted the Anti-Aliasing Filter

Conanair's response frequency band is 0-1,000Hz, but it intentionally allows high-frequency signals to pass through.

Intentionally "Folding Back"

Because the sampling speed is insufficient, impact vibrations of several kHz are "folded back" and recorded into the low-frequency band (within 0-1,000Hz) due to aliasing.

Why We Deliberately Omitted the Anti-Aliasing Filter

The raw waveform containing aliasing noise differs in shape from the original vibration waveform. However, the most important thing in bearing diagnosis is not the shape of the waveform itself, but "when the impact occurred (periodicity)."

Even if the Waveform is Distorted, "Timing Information (Periodicity)" is Preserved

Even if aliasing occurs, the timing (position on the time axis) when the impact occurred is preserved.

The Magic of Envelope Analysis

When envelope processing is applied to this "distorted raw waveform," surprisingly, almost the same periodic components (signs of damage) as those obtained via high-speed sampling are extracted.

Conclusion

Even if it is not correct as a "raw waveform," since the "periodic information" necessary for diagnosis is completely retained, accurate bearing diagnosis becomes possible.

4. On-site Benefits Brought by Undersampling Technology

Thanks to this undersampling technology, we were able to dramatically lower the hurdle for "continuous monitoring," which was difficult with conventional methods.

Overwhelming Power Savings

Since the amount of data can be significantly reduced, long-term operation on battery power is possible.

Hardware Simplification

It does not require expensive high-speed A/D converters, enabling multi-point installation at suppressed costs. Practical Predictive Maintenance: Realizing the "early detection of anomalies" that the field truly seeks with minimal infrastructure.

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |