Wi-Fi Wireless Vibration Sensors: Greater Flexibility in Factory Maintenance and the Benefits of Implementation

For factories seeking to streamline preventive maintenance, wireless vibration sensors are the ideal solution. This section examines how these sensors are transforming the future of equipment management and the tangible benefits they provide. If you're seeking affordable Wi-Fi-enabled wireless vibration sensors, please get in touch with NSXe.

- The Future of Equipment Management Transformed by Wi-Fi-Enabled Wireless Vibration Sensors

- Maximize Effectiveness with Easy Installation! Benefits of Implementing Wireless Vibration Sensors

- Flexible Installation and Optimized Implementation Costs

- Addressing Labor Shortages and Streamlining Maintenance Operations

- Comprehensive Equipment Health Assessment via Multi-Point Monitoring

- Key Points for Getting Started with Wi-Fi Equipment Monitoring Using Wireless Vibration Sensors

- Checking Wi-Fi Signal Strength and Installation Conditions Before Introducing Wireless Vibration Sensors

- conanair: Affordable, Compact, Waterproof Wireless Vibration Sensor

The stable operation of factory equipment is crucial for maintaining productivity and is a key factor influencing a company's competitiveness. However, equipment aging and unexpected failures can have significant impacts, including production line stoppages, increased costs, and safety risks. Traditional inspection methods faced challenges requiring substantial time, labor, and specialized expertise to monitor extensive equipment.

Under these circumstances, the importance of “preventive maintenance”—detecting signs of failure early and performing planned maintenance—has grown significantly. Wireless vibration sensors are gaining attention to efficiently achieve preventive maintenance, which was previously difficult with traditional inspections, at a reasonable cost. Specifically, affordable, compact Wi-Fi-enabled wireless vibration sensors enable easy installation and real-time monitoring, contributing to a deeper understanding of the health of equipment across entire factories.

This section introduces the future of equipment management transformed by wireless vibration sensors and the concrete benefits their implementation brings.

The Future of Equipment Management Transformed by Wi-Fi-Enabled Wireless Vibration Sensors

Affordable Wi-Fi-enabled wireless vibration sensors are fundamentally changing the concept of equipment management, where cost was traditionally a challenge, enabling more efficient and flexible preventive maintenance. Their ability to leverage existing infrastructure is accelerating their adoption.

Revolutionizing Data Collection and Enabling Real-Time Monitoring

Continuous data collection is essential for accurately assessing the health of factory equipment. Traditional wired vibration sensors required extensive wiring installation, limiting placement options and posing challenges in terms of implementation cost and labor.

Wireless vibration sensors liberate equipment management from these constraints. Among various wireless technologies, Wi-Fi-enabled sensors are a notable example. They leverage existing Wi-Fi network infrastructure already present in many factories, eliminating the need to build new communication networks and significantly lowering the barrier to entry.

Wi-Fi's high-speed data transfer capability enables the monitoring of extensive vibration raw waveform data. Immediately detecting signals indicating subtle vibration changes in equipment and identifying early signs of abnormalities is crucial for preventing sudden failures. This minimizes unplanned equipment downtime, contributing to stable production line operation.

Remote Equipment Diagnosis and Operational Efficiency Enhancement

Data collected by wireless vibration sensors can be accessed remotely via the internet from PCs, tablets, or smartphones. This enables real-time monitoring and diagnostics of equipment status from offices or remote locations, without the need to visit the site. This remote diagnostic capability proves especially effective for monitoring equipment in large-scale factories, hazardous areas, or places with restricted access.

Furthermore, when combined with a diagnostic system featuring an intuitive interface, it enables easy verification of equipment health and the detection of abnormalities, even without specialized knowledge of vibration analysis. This enables a wide range of personnel to understand equipment status and take necessary actions without relying solely on skilled technicians, promoting operational efficiency and labor savings throughout the entire equipment management process.

Maximize Effectiveness with Easy Installation! Benefits of Implementing Wireless Vibration Sensors

Wireless vibration sensors enable implementation in various environments, from large-scale factories to specific production lines, due to their ease of installation. This convenience is key to maximizing the effectiveness of preventive maintenance.

Flexible Installation and Optimized Implementation Costs

Traditional wired sensors required extensive wiring work. This not only imposed constraints on equipment placement but also often created barriers to implementation due to associated construction costs, time requirements, and potential production line stoppages.

Wireless vibration sensors eliminate the need for wiring, significantly reducing such labor and costs. Installation is completed simply by attaching the sensor directly to the target equipment, resulting in reduced installation time and minimizing the impact on production.

Furthermore, their wireless nature allows flexible placement in previously challenging locations such as confined spaces, hazardous areas with high temperatures or pressures, or on moving equipment like cranes. This enables the inclusion of all critical equipment within the factory under monitoring, achieving comprehensive preventive maintenance.

Addressing Labor Shortages and Streamlining Maintenance Operations

One major challenge facing modern manufacturing is the shortage of skilled maintenance technicians. Traditional methods, such as periodic patrols and visual inspections, require a significant number of human resources and heavily depend on the skills and experience of the inspectors.

Wireless vibration sensors enable the automation of these inspection tasks. Since the sensors continuously collect data, there is no longer a need for personnel to be on-site for constant inspections.

This allows limited personnel to focus on more advanced analysis and actual repair work, achieving overall efficiency and labor savings in maintenance operations. Furthermore, reducing the number of inspections in hazardous areas requiring human entry enhances worker safety. Automated data collection through measurement eliminates inspection variability, enabling preventive maintenance based on consistently objective and accurate information.

Comprehensive Equipment Health Assessment via Multi-Point Monitoring

A significant advantage is the high versatility, which allows for the efficient measurement of vibration data from multiple pieces of equipment using numerous wireless vibration sensors. In factories where many pieces of equipment are in operation, installing numerous inexpensive sensors on individual pieces of equipment to cover extensive automated measurement not only reduces implementation costs but also simplifies overall system management.

This enables a comprehensive understanding of the entire factory's equipment status, allowing for the evaluation of the health of each piece of equipment. It provides an overview to determine which equipment requires priority maintenance or which components show signs of deterioration, facilitating the creation of more strategic and efficient maintenance plans. As a result, it maximizes the overall production line uptime of the factory and contributes to enhancing the long-term value of equipment assets.

Key Points for Getting Started with Wi-Fi Equipment Monitoring Using Wireless Vibration Sensors

Equipment monitoring using wireless vibration sensors can be easily started by anyone as long as a Wi-Fi environment is available. Simply install the sensor on the equipment you want to monitor and connect it to the Wi-Fi network to complete the setup. Once installed, the vibration sensor automatically transmits collected signals, and the diagnostic system analyzes the data, allowing you to identify early signs of abnormalities in real time.

The key points for successful implementation are as follows:

- Selecting the installation location: Mount the sensor on a part where vibrations are clearly transmitted

- Confirming Wi-Fi connectivity: Ensure a stable communication environment

- Setting alarm thresholds: Adjust settings so notifications are sent when abnormalities are detected

By following these steps, you can continuously monitor equipment conditions without complex wiring or specialized expertise, helping prevent unexpected failures before they occur. Wireless vibration sensors support stable plant operations through their ease of installation and effective use of data.

Checking Wi-Fi Signal Strength and Installation Conditions Before Introducing Wireless Vibration Sensors

To use wireless vibration sensors reliably, it is important to check Wi-Fi signal strength and installation conditions in advance. In factory environments, communication can become unstable due to the influence of machinery, walls, and other structures.

By confirming that stable Wi-Fi coverage is available at the planned installation location, it becomes easier to prevent data transmission delays or data loss. In addition, selecting a mounting position where vibration is properly transmitted is essential.

The usability of wireless vibration sensors depends greatly on where they are installed and which signals are used. Organizing the communication environment before installation helps ensure smooth operation after deployment.

Points to Check in Advance

- Whether Wi-Fi signals are stable at the installation location

- Whether signals are obstructed by metal structures or walls

- Whether communication status can be checked after installation

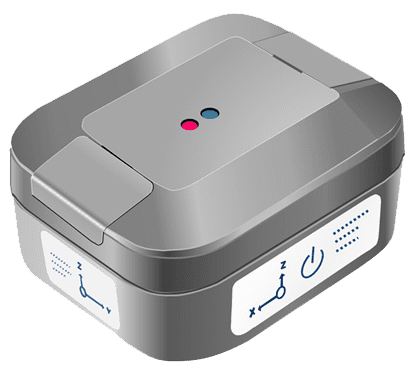

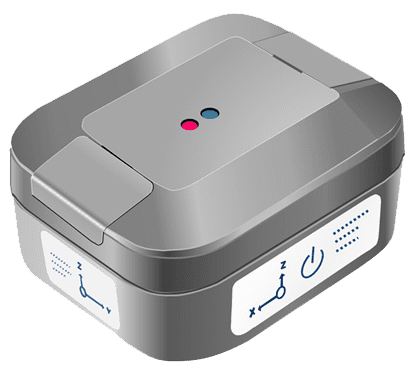

conanair: Affordable, Compact, Waterproof Wireless Vibration Sensor

NSXe.'s self-developed battery-powered, compact Wi-Fi vibration sensor, “conanair,” is a palm-sized smart sensor featuring a magnetic mount for easy installation. It can download raw waveform data for 96,000 points of X, Y, and Z-axis acceleration in approximately 2 seconds. Using the included FFT (Fast Fourier Transform) analysis app enables detailed bearing diagnostics. Its IP67 waterproof design and battery operation allow for maintenance-free operation.

In addition to enabling inspection measurements via smartphones or tablets, its automatic measurement mode allows for the permanent installation of unlimited units. This directly addresses the pressing issue of skilled worker shortages in industrial maintenance, enabling efficient monitoring of more equipment with fewer personnel.

The PC-based system allows setting warning and alarm thresholds for each measurement point, clearly displaying the 3-axis acceleration data.

An explosion-proof type suitable for hazardous locations, such as chemical plants, oil refineries, and paint factories, is also available. This model received the 36th Excellent Products and Technologies Award from the Small and Medium Enterprise Agency in 2024. With numerous implementation cases, over 2,500 units have been deployed as of April 2025.

New customers can try it for free for 30 days, so please don't hesitate to contact us for more information.

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |