Wireless Vibration sensors Pioneering New Equipment Monitoring! Explaining the Benefits of Improved Abnormal Condition Detection Accuracy and How to Choose

This section introduces the measurement transformation enabled by evolving wireless technology, the benefits of wireless vibration sensors, and how to select one based on your objectives, as well as key considerations during implementation. For wireless vibration sensors, consider NSXe's “conanair”.

- The Revolution in Vibration Measurement Brought by Evolving Wireless Technology

- Benefits of Improved Measurement Accuracy Using Wireless Technology

- Selecting Wireless Vibration Sensors for Specific Purposes and Key Considerations During Implementation

- Verifying Types and Functions of Wireless Vibration sensors

- Selection Considering Ease of Implementation and Operational Costs

- Evaluating Cost-Effectiveness and Support Structure

- The Convenience of Daily Monitoring Enabled by Wireless Vibration Measurement Technology

- Operational Practices to Make Wireless Vibration Meters Effective on Site

- Save cost and time while achieving stable operation with the Wi-Fi Vibration Monitor “conanair”!

In planned equipment monitoring, essential for stable factory operation, wired vibration sensors?previously the mainstream?presented challenges such as installation hassles and location constraints.

Wireless vibration sensors solve these issues and revolutionize equipment monitoring. Advances in wireless technology have significantly enhanced the flexibility and efficiency of vibration measurement, enabling real-time monitoring of abnormal conditions.

Here, we introduce the measurement revolution brought about by evolving wireless technology, the benefits of improved measurement accuracy, how to choose the right option based on your purpose, and key points to note during implementation.

The Revolution in Vibration Measurement Brought by Evolving Wireless Technology

Wireless vibration monitors fundamentally change the concept of vibration measurement, enabling more flexible and efficient monitoring of equipment.

The Diversity and Convenience of Wireless Communication Technologies (Including Wi-Fi)

Traditional wired vibration sensors required extensive wiring work for sensor installation. This posed challenges, including location constraints, the complexity of installing them on intricate equipment, and high installation costs, making the application particularly difficult in vast factories or on equipment located in high-temperature or hazardous areas. However, wireless communication technology fundamentally resolves these issues.

Wireless vibration monitors utilize a wide range of wireless protocols, including Wi-Fi and Bluetooth. Each protocol has distinct characteristics regarding communication range, data transfer speed, and power consumption.

Among these, Wi-Fi offers convenience. Its widespread adoption, as it exists in many existing network infrastructures in factories, eliminates the need to build new communication networks, thereby lowering the barrier to entry. This makes it easy to install sensors on numerous pieces of equipment, which was difficult with wired systems, dramatically improving the flexibility and efficiency of vibration measurement. The shift to wireless frees us from physical constraints, enabling more comprehensive monitoring of equipment. Wi-Fi can transmit large amounts of information, including raw vibration waveforms, making it applicable for various analyses such as precision diagnostics and AI applications.

Real-Time Data Collection and Remote Monitoring

The core measurement transformation brought by wireless vibration monitors lies in enabling real-time anomaly monitoring through data collection and remote surveillance. Wireless communication allows vibration sensors to continuously acquire data from equipment operation 24/7, 365 days a year, and transmit it to a central system. This eliminates the need for personnel to visit sites periodically for measurements, freeing up time and effort while ensuring constant awareness of the latest equipment’s status.

Data collected for real-time anomaly monitoring can be viewed remotely from offices or control rooms via PCs, tablets, or smartphones. This enables centralized management of equipment status across vast factory grounds. When signs of an anomaly are detected, the system immediately issues an alert and notifies personnel responsible, allowing for swift initial response. By eliminating the need for on-site personnel, monitoring efficiency improves dramatically, allowing limited staff to be reassigned to more strategic tasks. This enhances equipment maintenance quality while contributing to labor cost optimization.

Benefits of Improved Measurement Accuracy Using Wireless Technology

Wireless vibration sensors not only offer installation flexibility but also enhance measurement data accuracy and reliability, enabling more precise equipment diagnostics and preventive maintenance.

High-Precision Measurement Data Through Optimized Data Transmission

Wired systems risk precision loss during the transmission of analog signals. Wireless vibration sensors digitize analog signals at the sensor and transmit them wirelessly. This digital data transmission reduces the risk of signal degradation, enabling the acquisition of cleaner, higher-precision vibration data.

High-precision data accurately captures subtle signs of equipment abnormalities, dramatically improving fault prediction accuracy. High-quality data also enhances the reliability of frequency analysis and AI analysis, forming the foundation for accurate diagnostic results.

Establishing Reliability Through Continuous Data Collection and Diagnostics

The introduction of wireless vibration monitors enables continuous data collection 24 hours a day, 365 days a year. This monitoring system accumulates vast amounts of time-series data regarding the health of equipment. Identifying long-term trend changes enables more accurate predictions of equipment degradation rates and the progression of failures.

Collected data is analyzed in real time, triggering immediate alerts upon anomaly detection. This eliminates the need for constant human monitoring, significantly reducing the risk of oversight. Objective diagnostics based on data reduce reliance on human experience, enhancing the reliability of diagnostic results.

Selecting Wireless Vibration Sensors for Specific Purposes and Key Considerations During Implementation

To successfully implement wireless vibration sensors, it is crucial to understand how to select them in accordance with your company's objectives and to be aware of specific considerations during implementation.

Verifying Types and Functions of Wireless Vibration sensors

When selecting a wireless vibration meter, it is essential to consider the following factors. Specifications vary widely, including measurement frequency range, sensitivity, battery life, and sampling rate. Wireless communication methods also differ, such as Wi-Fi and Bluetooth. It is a combination of communication range, data transfer speed, and power consumption.

Avoid fixating on a specific wireless method; compare multiple options to build the optimal measurement environment.

Selection Considering Ease of Implementation and Operational Costs

When selecting a wireless vibration meter, it is essential to consider both the ease of implementation and operational costs comprehensively. Products featuring a compact main unit and lower initial implementation costs offer significant advantages for deploying across numerous pieces of equipment or for companies with budget constraints.

Furthermore, an intuitive system that allows easy connection and operation via a browser on standard devices (such as tablets or smartphones), even without specialized knowledge, ensures smooth post-implementation operation and reduces the learning burden on employees.

This high level of operability greatly facilitates routine equipment monitoring and is crucial for ensuring the system becomes firmly established on-site. Products with simplified installation and operation are particularly suitable when considering transitioning from manual inspections to automated measurements for general-purpose machinery.

Evaluating Cost-Effectiveness and Support Structure

Implementing wireless vibration sensors is an investment. To maximize its cost-effectiveness, it is vital to evaluate both the costs and the post-implementation support structure. Comprehensively understand not only the initial cost of the sensor units but also the total running costs, including the data collection system, software, and ongoing operational and maintenance expenses, and compare these against your company's budget.

Furthermore, the post-implementation support structure is a critical selection factor. The vendor's support quality, technical expertise, and ability to respond quickly to issues directly impact the system's stable operation. Choose a reliable vendor by considering their implementation track record and customer reputation. Comprehensive support is crucial for reducing your burden from system implementation through operation and troubleshooting, ensuring you achieve a solid return on your investment.

The Convenience of Daily Monitoring Enabled by Wireless Vibration Measurement Technology

Wireless vibration meters are gaining attention as a technology that makes equipment monitoring easier and more efficient. Locations that were difficult to monitor with traditional wired systems can now be handled easily using wireless solutions. This enables real-time visibility into equipment operating conditions and allows for faster response to potential issues.

- High Installation Flexibility

Because no wiring is required, wireless vibration meters can be installed on equipment in confined spaces or high-temperature environments that were previously difficult to access. - Immediate Data Collection

Early signs of abnormalities are detected in real time and alerts are automatically issued, helping reduce the workload on on-site personnel. - Optimized Operating Costs

Battery-powered, Wi-Fi?enabled wireless vibration meters reduce the need for wiring work and minimize maintenance labor, contributing to lower overall operating costs.

By leveraging wireless technology, vibration meters improve the accuracy and efficiency of daily equipment monitoring, becoming a powerful tool that supports stable operation across the entire plant.

Operational Practices to Make Wireless Vibration Meters Effective on Site

Simply introducing wireless vibration meters does not guarantee results. To achieve meaningful benefits, it is essential to create systems that allow them to be used naturally in daily operations.

For example, defining how abnormal alerts should be checked in advance helps prevent inconsistent responses among personnel. Providing an environment where inspection results can be easily shared also raises awareness of equipment conditions.

Wireless vibration meters are technically advantageous because they are easy to use and require no specialized operation. Precisely for this reason, avoiding complex rules and integrating them seamlessly into routine inspections leads to continuous monitoring and stable operation.

Save cost and time while achieving stable operation with the Wi-Fi Vibration Monitor “conanair”!

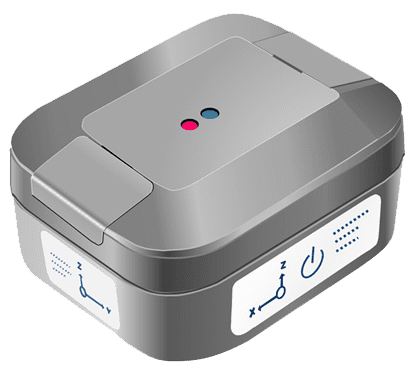

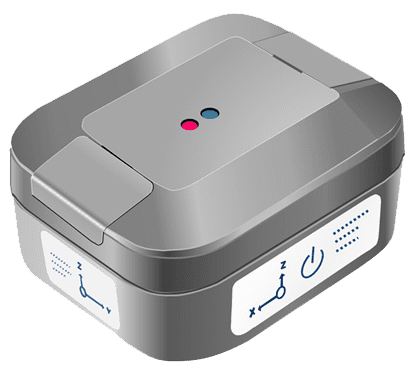

NSXe offers the Wi-Fi Vibration Monitor “conanair”. This is an affordable vibration sensor that fits in the palm of your hand. Magnetic mounting eliminates the need for electrical wiring. Battery-powered operation ensures maintenance-free use. Download raw waveform data from all three X, Y, and Z-axis accelerometers?totaling 96,000 points?in approximately 2 seconds. The included FFT (Fast Fourier Transform) analysis app enables detailed bearing diagnostics. The data is compatible with many tools and integrates easily with existing or new systems. It achieves cost-effective bearing anomaly detection using under-sampling (patented technology) that defies conventional wisdom.

A single PC can control up to 100 units, and multiple computers can be connected to control hundreds of conanair units simultaneously.

For more information about the product, please do not hesitate to contact us.

30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying: Try equipment anomaly detection and predictive maintenance for free. Please feel free to contact us.30-Day Free Trial & Inquiry

Try Conan Air for free for 30 days. Here is what our users are saying:- Easy installation for immediate use

- No app required; operate via web browser

- No cloud required for fully automatic measurement

- Affordable, including dedicated software

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00~17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://conanair.com/ |