As a business, it is important to keep updated on the health of your employees and machines. However, this is easier said than done as businesses still have their daily tasks to do too. Therefore, why not use conanair to make your work tasks easier? But do not take the word from this brief summary. The company for conanair has done experiments to show the world how it is useful.

Introduction

As a business leader, do you feel overwhelmed with daily tasks or responsibilities? Most of the time, you have to keep a check on the workflow and be aware of the health of your employees and machine. However, when a leader is overwhelmed, how far can leaders go? If this is you, why not use NSXe Co. LTD’s conanair? A tool that makes your leadership tasks a little easier.

What we do at NSXe Co. LTD.

NSXe Co. LTD is a Japan-based company that specializes in providing service for mechanical equipment installation and maintenance. The company mainly works with the following types of businesses, such as factories, gasoline stands, hotels, golf courts, etc. Their past achievements include reducing energy usage and cost by 20% at major Japanese hospitals through equipment maintenance and control. Additionally, they have cut energy costs and waste by 15% at large shopping centers by placing those maintenance tools in refrigerated showcases, lightbulbs, and other electric-dependent tools. Recently, NSXe. Co. LTD has released a Wi-Fi vibration sensor known as conanair in the United States.

What is Vibration Sensor and Failure Detection About?

A vibration sensor is a method or technique where it measures vibration level in machinery for screening and analysis. General types of vibration sensor include displacement sensors, velocity sensors, and acceleration. Vibration sensors are typically used for failure detection, such as bearing failure, broken gears, running outside system parameters, electrical faults, belt issues, and cracked shafts. This is possible because when a bearing is damaged, high-frequency impact vibrations are generated.

About conanair

conanair promotes itself for being a “low-cost vibration sensor.” The concept of conanair came from the idea of using the 3-dimensional accelerometer sensor commonly found in smartphones. The device includes inexpensive Micro Electro Mechanical Systems (MEMS), an accelerometer equivalent to the orientation-sensing sensors for smartphones and Wi-Fi modules.

What Are Wi-Fi Vibration Sensors About?

The significance of conanair is its failure detection by using “Wi-Fi Vibration Sensors”. To a certain point, it was believed that failure detection was only possible through expensive and high-resolution vibration sensors. Furthermore, most believed that inexpensive digital output sensors with low-sampling frequencies cannot measure such vibrations, or that high-frequency impact vibrations create a large fold-back noise that impedes measurement. However, conanair was able to subdue those expectations.

conanair is a small device that can be placed on top of the machine’s surface. The business can check the health of the machine. Furthermore, the device provides raw and real-time data about the machine. conanair performs a physical examination similar to how a human doctor listens to a patient’s heart.

The Advantages Of Using Wi-FI Vibration Sensors

- Most people might associate the word “wireless” with Wi-Fi. Generally, “wireless” implies that businesses do not have to worry about running cords or wires through walls or ceilings. Depending on the business’s environment, this will be a financial advantage. Additionally, “wireless” is excellent at covering large and remote areas.

- Wi-Fi Vibration Sensors can be monitored with simple internet access. With one computer and a single connection, a business can monitor the health of the machines. Since business personnel does not have to leave their computer, this can save time for certain businesses.

Other Specifications Of conanair

- Sensor Type: Digital Accelerator Sensor ADXL345, created by ANALOG DEVICES

- Supporting Frequency Level: 10 – 1,000 Hz

- Data Sampling Wavelength: 3,200 Hz

- The Size: 65 x 52 x 32 mm

- The Weight is 77 g

What is “Under Sampling” Technology?

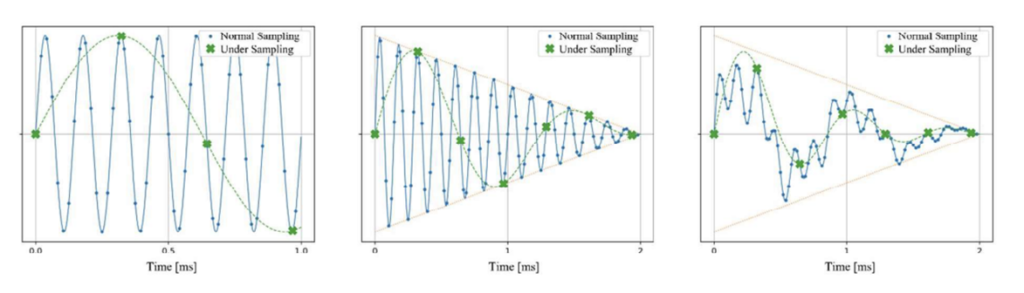

“Under Sampling” is a type of technology commonly used in wireless communication systems that handles high-frequency signals. Under Sampling is also known as band pass sampling, and harmonic sampling. The technology is used to capture vibrations, enabling diagnosis of bearing fault.

This is the comparison between normal and undersampling for sine and complicated waveforms.

Despite this, the common belief was that inexpensive digital output sensors with low-sampling frequency cannot measure vibrations necessary for businesses. However, NSXe confirmed that this is possible through the usage of general-purpose vibration sensors with “Under Sampling” capability. This is NSXe’s conanair. conanair uses the data including aliasing noise through “Under Sampling.”

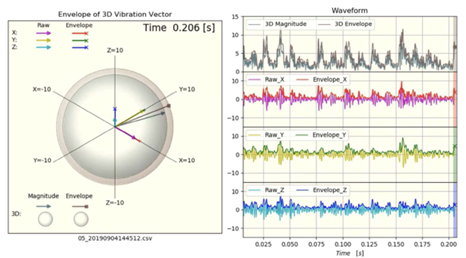

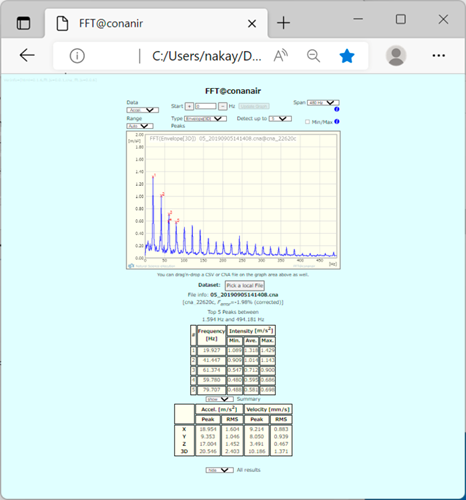

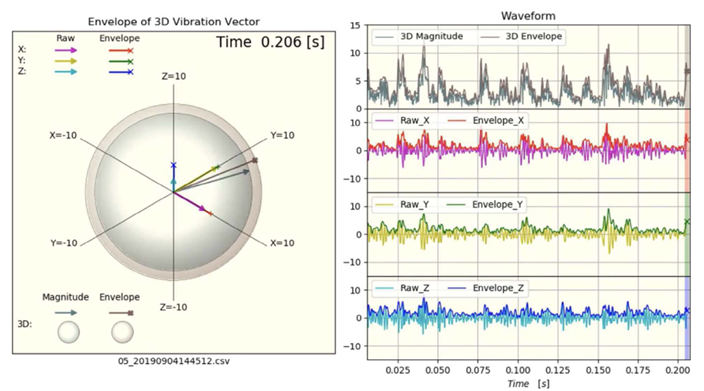

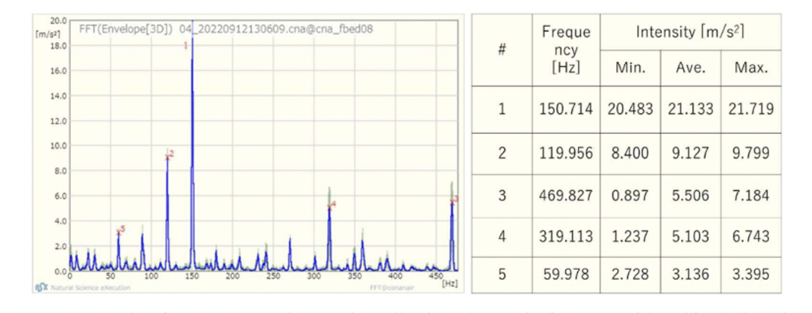

Additionally, it performs frequency analysis through Fast Fourier Transform. The following figure is the measured acceleration vibration waveforms from each 3D axis. The x-axis represents conanair’s long-side measurement, y-axis represents the short-side measurements, and the z-axis represents the horizontal direction.

Sample Usage And Results Of conanair

Purpose Of The Experiment

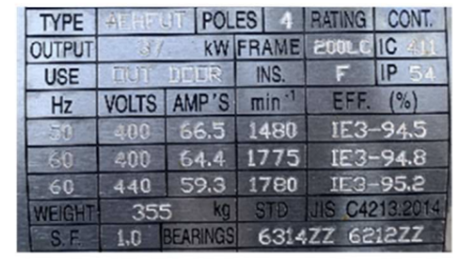

Previously, it was mentioned that there is a common understanding that only expensive tools can detect failure. To prove this is not true, certain experiments were performed using conanair. On September 12, 2022, NSXe Co. LTD conducted an experiment by installing conanair near the bearing (drive side) of the motor of the water pump. Figure 3.1 shows the features and details of the water pump used for the experiment.

Data And Results Collected From The Experiment

After collecting measurements with conanair, NSXe Co. LTD were able to determine a damage at the inner ring of #6314 bearing. The bearing performed at 1780 rpm and 3D envelope FFT. Additionally, there were vibrations of 121.11 Hz at the outer ring of #6212 bearing.

Through the usage of Under Sampling Technology, issues within the water pump were found for inexpensive pricing. Furthermore, there is a common belief that inexpensive vibration sensors cannot find issues within machines or systems. However, this simple experimentation proved that this is the opposite. “conanair,” an inexpensive wireless device, found issues within the outer rings of a water pump.

What Are The Future Plans For “conanair”

- NSXe Co. LTD began its digital marketing of conanair through Engineering 360, an online database.

https://www.globalspec.com/specsearch/partspecs?partId={6FFA8E2F-947B-4AB7-A9D5-F891DA7B76F8}&comp=109&vid=489633&sqid=107562511 - Currently, conanair still needs to meet usage for hazardous areas. NSXe Co. LTD is developing an explosion-proof model. The release of this model is expected to occur at the end of 2023.

- At the time of the experiment, conanair can only detect outliers and notify them to business. Currently, there are plans for major overhauls which includes plans to be more precise on determining damages.

We will continue to evolve conanair in various ways. if you would like to see it in person or try it out for yourself, please contact us using the form.